29.43 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 10 mm

Panel size: 1090 X 1020 mm

Total surface of 1 panel: 1.11 m2

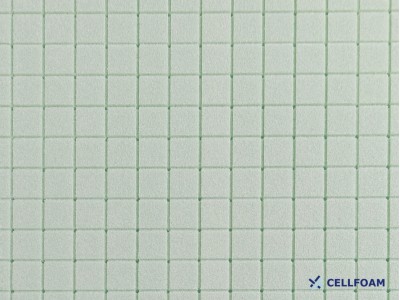

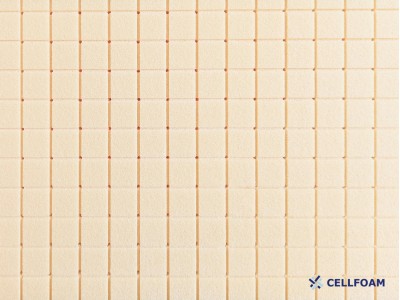

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

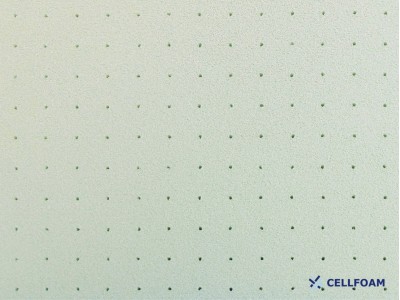

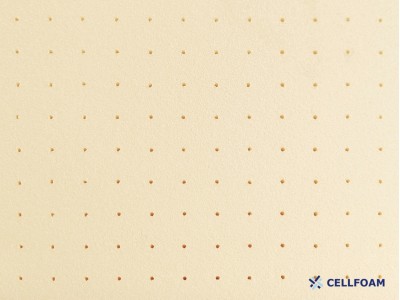

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

29.43€

40.35 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 15 mm

Panel size: 1090 X 1020 mm

Total surface of 1 panel: 1.11 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

40.35€

48.59 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 20 mm

Panel size: 1090 X 1020 mm

Total surface of 1 panel: 1.11 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

48.59€

52.35 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 20 mm

Panel size: 1000 X 1070 mm

Total surface of 1 panel: 1.07 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

The HT type is suitable for high temperature applications. For example, it can be used for autoclave prepreg sandwich curing at 120°C and 3 bar pressure. Higher temperature and pressure applications are possible, depending on the tolerance for potential partial collapse (collapse refers to a reduction in thickness without implying a loss of mechanical properties).

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

52.35€

59.30 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 25 mm

Panel size: 1090 X 1020 mm

Total surface of 1 panel: 1.11 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed cell PVC foam with holes and grooves for infusion. Holes allow the resin to pass easily through the foam while the grooves on the underside act to distribute the resin and aid flow on the underside. Its excellent stiffness, strength to weight ratio, and high toughness make it suitable for a large variety of applications. It can be shaped with wood tools, sandpaper and can be thermoformed to curves. The foam is ideally suited for statically and dynamically loaded structures and is compatible to all resin systems.

Main characteristics:

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

59.30€

62.46 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 25 mm

Panel size: 1000 X 1070 mm

Total surface of 1 panel: 1.07 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

The HT type is suitable for high temperature applications. For example, it can be used for autoclave prepreg sandwich curing at 120°C and 3 bar pressure. Higher temperature and pressure applications are possible, depending on the tolerance for potential partial collapse (collapse refers to a reduction in thickness without implying a loss of mechanical properties).

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

62.46€

69.18 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 30 mm

Panel size: 1090 X 1020 mm

Total surface of 1 panel: 1.11 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

69.18€

71.80 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 30 mm

Panel size: 1000 X 1070 mm

Total surface of 1 panel: 1.07 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

The HT type is suitable for high temperature applications. For example, it can be used for autoclave prepreg sandwich curing at 120°C and 3 bar pressure. Higher temperature and pressure applications are possible, depending on the tolerance for potential partial collapse (collapse refers to a reduction in thickness without implying a loss of mechanical properties).

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

71.80€

87.59 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 40 mm

Panel size: 1000 X 1070 mm

Total surface of 1 panel: 1.07 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

The HT type is suitable for high temperature applications. For example, it can be used for autoclave prepreg sandwich curing at 120°C and 3 bar pressure. Higher temperature and pressure applications are possible, depending on the tolerance for potential partial collapse (collapse refers to a reduction in thickness without implying a loss of mechanical properties).

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

87.59€

106.87 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 50 mm

Panel size: 1000 X 1070 mm

Total surface of 1 panel: 1.07 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

The HT type is suitable for high temperature applications. For example, it can be used for autoclave prepreg sandwich curing at 120°C and 3 bar pressure. Higher temperature and pressure applications are possible, depending on the tolerance for potential partial collapse (collapse refers to a reduction in thickness without implying a loss of mechanical properties).

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

106.87€

Showing 1 to 10 of 10 (1 Pages)