Epoxy trowelable system Mixfill 80 for fairing

Each kilo includes 0.57 kg resin + 0.43 kg hardener

Mixfill 80 is a filled coating formulated based on flexibilized epoxy systems and with high mechanical performance at high percentages of elongation to break (8-15%) and a good impact resistance. Coating is filled under vacuum with a complex of very low density fillers (~ 0.6) and low abrasive power in order to ensure greater sustainability of sanding and machining without scrub tools.

Epoxy system Mixfill 80:

- Excellent quality of application without microbubbles

- Ease of application to the rule or the spatula

- Excellent sandability with flat sanding or sander

- Very low clogging of the abrasive

- Great fineness of the film

- No drying shrinkage during drying

- Low exotherm in thick

- Excellent impact resistance

- Ease of dosing by volume (1/1)

PROPERTIES

Physical properties of Mixfill 80 base:

Aspect / colour: Grey paste

Viscosity (m.Pas) at 20 oC / 68 oF: 71900 ± 14400

Density at 20 oC / 68 oF: 0.6500

Physical properties of Mixfill 80 hardener:

Aspect / colour: White paste

Viscosity (m.Pas) at 20 oC / 68 oF: 106000 ± 21200

Density (g/cm3): 0.4800

Mix properties of Mixfill 80 system:

Weight ratio: 100 / 75 g

Volume ratio: 100 / 100 ml

Mix viscosity (m.Pas) at 20 oC / 68 oF: 106000 ± 21200

Reactivity of Mixfill 80 system:

Exothermic temperature on 500 g mix (oC) at 20 oC: 111 oC

Time to reach exothermic peak on 500 g mix at 20 oC: 52'

Pot life of 500 g mix at 20 oC: 34'

Intrastat Number for this product: Epoxy: 39073000, Hardener: 29213091..

From 27.71€ ...to 42.96€

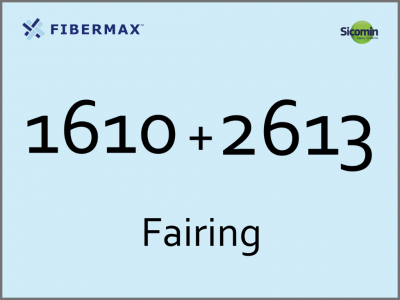

Versatile epoxy system SR1610 / SD2613 for fairing

Each kilo includes 0.68 kg resin + 0.32 kg hardener

SR1610 / SD2613 is a versatile epoxy formulation designed to mix with hollow microspheres and inorganic fillers. It can adhere to epoxy, polyester, vinylester and polyurethane resins. It is used for the manufacturing of putties for sandable coating from medium to fine grain. It exhibits temperature resistance over 100°C.

PROPERTIES

Mix properties of SR1610 / SD2613 system:

Weight ratio: 100 / 47 g

Volume ratio: 100 ml / 50 ml (or 2/1)

Reactivity of SR1610 / SD2613 system:

Pot life of 500 g mix at 20 oC: 60'

Working time of 3 mm thick coat of putty at 20 oC: 2 hrs

Putty in a coat of 3 mm sandable at 20 oC after: 20 hrs

Intrastat Number for this product: Epoxy: 39073000, Hardener: 29213091..

From 21.15€ ...to 32.78€

Showing 1 to 2 of 2 (1 Pages)