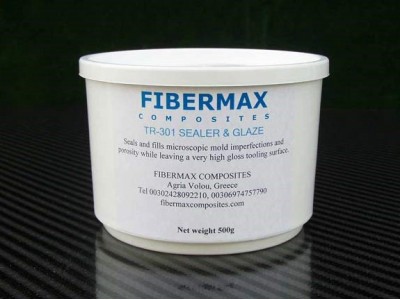

Primer for mold release

DIRECTIONS

Shake well before using. Apply a small amount to the clean surface. Machine buff to thoroughly clean, seal, and finish the surface. On new molds 2 coats are recommended to adequately fill the microscopic pores. Wipe off excess with a clean soft towel and release as required. Keep container sealed when not in use.

Intrastat Number for this product: 34049000..

9.90€

Primer for mold release

DIRECTIONS

Shake well before using. Apply a small amount to the clean surface. Machine buff to thoroughly clean, seal, and finish the surface. On new molds 2 coats are recommended to adequately fill the microscopic pores. Wipe off excess with a clean soft towel and release as required. Keep container sealed when not in use.

Intrastat Number for this product: 34049000..

61.44€

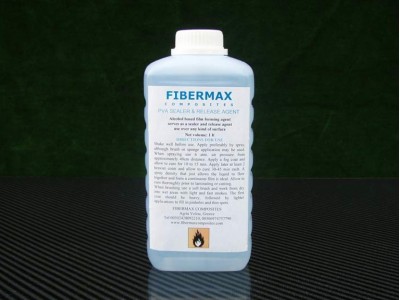

PVA release agent, high temperature

Price: 14.30 EUR / container of 1.0 lt

Polyvinyl alcohol W324 has excellent film forming and release properties. It is used as a release agent in molds and prototypes that are repaired or sanded and do not have a shiny surface. It is resistant to oil, grease and solvents. It is odorless and nontoxic. It has high tensile strength and flexibility. These properties are dependent on humidity, in other words, with higher humidity more water is absorbed. The water, which acts as a plasticiser, will then reduce its tensile strength, but increase its elongation and tear strength. W324 can be use for both room and high temp applications. W324 is fully degradable and is a quick dissolver.

DIRECTIONS

Apply with spray or soft sponge and let dry thoroughly. When using a sponge move with strokes from dry to wet areas. To remove after use or help demolding apply water with pressure. A new, fresh coat must be applied after each and every demolding.

Intrastat Number for this product: 27121090..

14.30€

PVA release agent, high temperature

Polyvinyl alcohol W324 has excellent film forming and release properties. It is used as a release agent in molds and prototypes that are repaired or sanded and do not have a shiny surface. It is resistant to oil, grease and solvents. It is odorless and nontoxic. It has high tensile strength and flexibility. These properties are dependent on humidity, in other words, with higher humidity more water is absorbed. The water, which acts as a plasticiser, will then reduce its tensile strength, but increase its elongation and tear strength. W324 can be use for both room and high temp applications. W324 is fully degradable and is a quick dissolver.

DIRECTIONS

Apply with spray or soft sponge and let dry thoroughly. When using a sponge move with strokes from dry to wet areas. To remove after use or help demolding apply water with pressure. A new, fresh coat must be applied after each and every demolding.

Intrastat Number for this product: 27121090..

126.15€

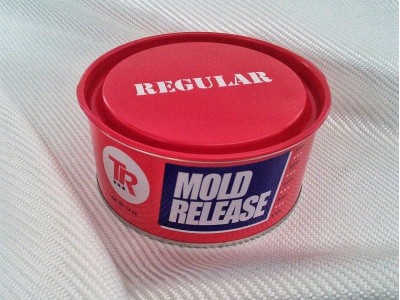

Mold release wax

14.90 EUR / container of 400 g

DIRECTIONS

Apply using a circular, overlapping motion, an even moist film. Allow TR 102 Regular and TR 104 Hi Temp to dry to uniform haze, usually within 5-10 minutes. Hand wipe with a clean dry cloth. For new tooling, it is highly recommended to use the TR 301 Sealer Glaze to improve gloss and seal mold surface. Five to six coats of the paste wax release are normally required for best results. After polish wipe, allow a minimum of 30 minutes between coats for the wax to dry.

Conversion data: 400 g = 14 oz

Intrastat Number for this product: 27121090..

14.90€

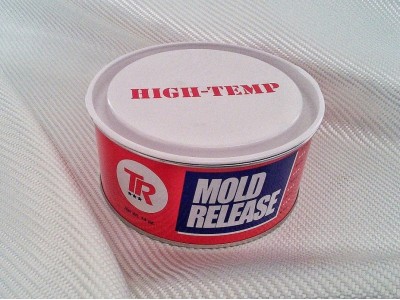

Mold release wax, high temperature

16.48 EUR / container of 400 g

DIRECTIONS

Apply using a circular, overlapping motion, even moist film. Allow TR 102 Regular and TR 104 Hi Temp to dry to uniform haze, usually within 5-10 minutes. Hand wipe with a clean dry cloth. For new tooling, it is highly recommended to use the TR 301 Sealer Glaze to improve gloss and seal mold surface. Five to six coats of the paste wax release are normally required for best results. After polish wipe, allow minimum of 30 minutes between coats to allow the wax to set.

Conversion data: 400 g = 14 oz

Intrastat Number for this product: 34049000..

16.48€

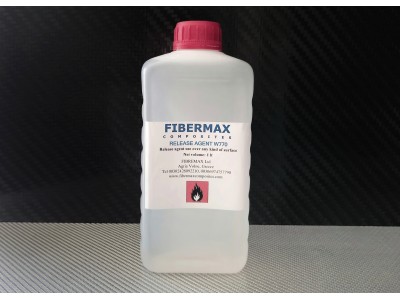

Epoxy mould release agent, high temperature

W770 is a versatile, fast evaporating release agent that offers excellent release for various moulding applications. It is odorless, offers high gloss and slip and doesn' t form mold build up. It cures at room temperature and can be applied to mold surfaces at room temperature up to 60 oC.

DIRECTIONS

Apply by spraying, brushing or wiping with a clean lint-free cloth. When spraying, ensure a dry air source is used or use an airless spray system. If possible, before applying W770, warm the mold to approximately 50 oC in order to drive off any moisture entrapped on the mold surface.

Intrastat Number for this product: 27121090..

30.44€

Glossy film forming agent, in liquid form, which serves as a sealer and release agent over any kind of surface.

DIRECTIONS

Shake well before use. Apply preferably by spray, although brush or sponge application may be used. When spraying use a gun with a 1 mm nozzle and use only 1.5-2.0 kg/cm3 air pressure. Apply a fog coat and allow to cure for 10 to 15 min. Apply later a heavier coat and allow to cure. A third coat is required until a continuous film (0.5 - 0.8 mm) is formed. Allow to cure thoroughly prior to laminating or casting. When brushing use a soft brush and work from dry into wet areas with light and fast strokes. The first coat should be heavy, followed by lighter applications to fill in pinholes and thin spots.

TO REMOVE COATING

If film is of the proper thickness it can be blown off with an air nozzle. If not, remove with acetone.

Intrastat Number for this product: 39011090..

21.42€

Glossy film forming agent, in liquid form, which serves as a sealer and release agent over any kind of surface.

DIRECTIONS

Shake well before use. Apply preferably by spray, although brush or sponge application may be used. When spraying use a gun with a 1 mm nozzle and use only 1.5-2.0 kg/cm3 air pressure. Apply a fog coat and allow to cure for 10 to 15 min. Apply later a heavier coat and allow to cure. A third coat is required until a continuous film (0.5 - 0.8 mm) is formed. Allow to cure thoroughly prior to laminating or casting. When brushing use a soft brush and work from dry into wet areas with light and fast strokes. The first coat should be heavy, followed by lighter applications to fill in pinholes and thin spots.

TO REMOVE COATING

If the film is of the proper thickness it can be blown off with an air nozzle. If not, remove with acetone.

Intrastat Number for this product: 39011090..

76.80€

Showing 1 to 9 of 9 (1 Pages)