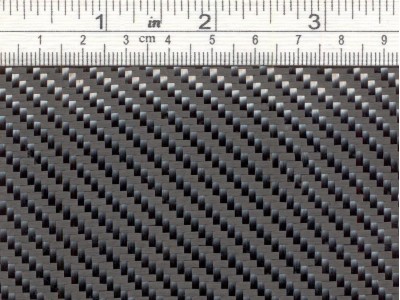

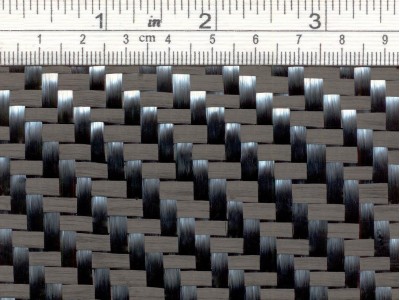

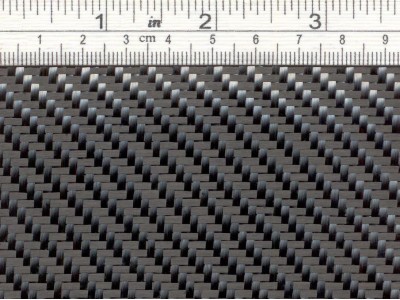

Carbon prepreg C90Ppp 1K, optimized for hot press, 30 sq.m. roll

Price: 2414.40 EUR / 30 sq.m. roll

Price / sq.m.: 80.48 EUR

TECHNICAL CHARACTERISTICS

Fabric weight: 92 g / sq.m.

Weaving style: Plain

Width: 1.00 meter

Prepreg weight: 167 g / sq.m.

Epoxy content: 45%

Volatile content: < 1%

Warp: 1K T300 carbon fiber, 50%, 7 ends(threads) / cm

Weft: 1K T300 carbon fiber, 50%, 7 ends / cm

Fibermax general purpose prepregs are based on a 80 to 150 oC (176 - 302 oF) curing toughened epoxy matrix, suited for both autoclave and press molding applications. A standard autoclave curing cycle is: Draw vacuum (0.6 - 0.7 bar) and apply positive pressure. Then start heating - typically 2-5 oC / min (3.5 - 9 oF) - till 120 oC (248 oF) and then hold this temperature for 1 hour. Turn off the temperature and cool under pressure to 60 oC (140 oF). When fully cooled open the bag and extract the piece.

STORAGE LIFE

12 months at - 18 oC

4 - 6 weeks at room temperature

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

EVALUATED Tg FOR RESPECTIVE CURING CYCLE

1 hour at 120 oC (248 oF): 110 - 120 oC (230 - 248 oF)

1 hour at 130 oC (266 oF): 130 - 140 oC (266 - 284 oF)

10 min at 150 oC (302 oF): 130 - 150 oC (266 - 302 oF)

TYPICAL MECHANICAL PROPERTIES OF LAMINATE

Cured at 130 oC for 60 minutes and 3 bar

Flexural strength (Mpa): 850

Flexural modulus (Gpa): 54

Tensile strength (MPa): 550

Tensile modulus (GPa): 60

ILSS - Short Beam Shear (Mpa): 67

Tg (DSC) 20 oC / min: 128 oC

Please click on picture, for a closer view to the fabric's real size. To realize actual size with precision please observe the threads / cm feature mentioned above.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibremax Ltd reserves the right to make modifications on fabrics, change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request with roll serial number.

Intrastat Number for this product: 68151200..

2,414.40€

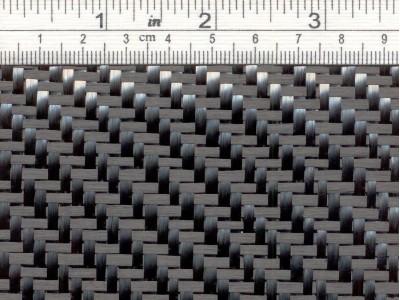

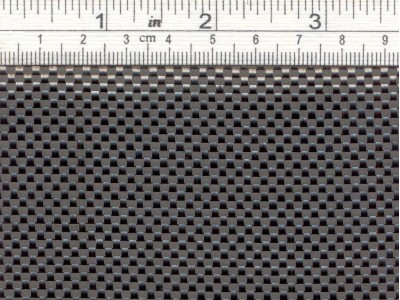

Carbon prepreg C160Ppp, general purpose, 40 sq.m. roll

Price: 1364.80 EUR / 40 sq.m. roll

Price / sq.m.: 34.12 EUR

TECHNICAL CHARACTERISTICS

Fabric weight: 160 g / sq.m.

Width: 1.00 meter

Prepreg weight: 291 g / sq.m.

Epoxy content: 45 %

Gel time at 125 oC: 6-9 min

Volatile content: < 1 %

Weaving style: Plain

Warp: 3K TR30S carbon fiber, 50%, 4 ends(threads) / cm

Weft: 3K TR30S carbon fiber, 50%, 4 ends(threads) / cm

Fibermax general purpose prepregs are based on a 80 to 150 oC (176 - 302 oF) curing toughened epoxy matrix, suited for both autoclave and press molding applications. A standard autoclave curing cycle is: Draw vacuum (0.6 - 0.7 bar) and apply positive pressure. Then start heating - typically 2-5 oC / min (3.5 - 9 oF) - till 120 oC (248 oF) and then hold this temperature for 1 hour. Turn off the temperature and cool under pressure to 60 oC (140 oF). When fully cooled open the bag and extract the piece.

STORAGE LIFE

12 months at - 18 oC

4 - 6 weeks at room temperature

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

EVALUATED Tg FOR SUGGESTED CURING CYCLE

1 hour at 125 oC: 120 - 125 oC

2 hours at 110 oC: 120 - 125 oC

TYPICAL MECHANICAL PROPERTIES OF LAMINATE

Cured by hot press technology at 125°C curing cycle

Flexural strength (Mpa): 800

Flexural modulus (GPa): 54

ILSS - Short Beam Shear (Mpa): 64

Please click on picture, for a closer view to the fabric's real size. To realize actual size with precision please observe the threads / cm feature mentioned above.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibremax Ltd reserves the right to make modifications on fabrics, change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request with roll serial number.

Intrastat Number for this product: 68151200..

1,364.80€

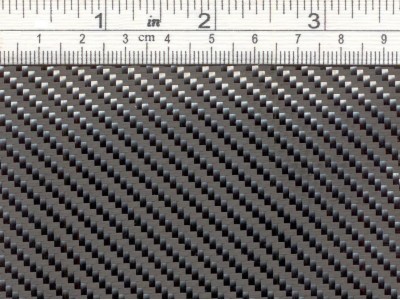

Carbon prepreg C160T2pp, general purpose, 40 sq.m. roll

Price: 1476.72 EUR / 40 sq.m. roll

Price / sq.m.: 36.92 EUR

TECHNICAL CHARACTERISTICS

Fabric weight: 160 g / sq.m.

Width: 1.00 meter

Prepreg weight: 394 g / sq.m.

Epoxy content: 42 %

Gel time at 125 oC: 11 min

Volatile content: < 1 %

Weaving style: Twill 2X2

Warp: 3K TR30S carbon fiber, 50%, 5.25 ends(threads) / cm

Weft: 3K TR30S carbon fiber, 50%, 5.25 ends / cm

Fibermax general purpose prepregs are based on a 80 to 150 oC (176 - 302 oF) curing toughened epoxy matrix, suited for both autoclave and press molding applications. A standard autoclave curing cycle is: Draw vacuum (0.6 - 0.7 bar) and apply positive pressure. Then start heating - typically 2-5 oC / min (3.5 - 9 oF) - till 120 oC (248 oF) and then hold this temperature for 1 hour. Turn off the temperature and cool under pressure to 60 oC (140 oF). When fully cooled open the bag and extract the piece.

STORAGE LIFE

12 months at - 18 oC

4 - 6 weeks at room temperature

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

EVALUATED Tg FOR RESPECTIVE CURING CYCLE

1 hour at 120 oC (248 oF): 110 - 120 oC (230 - 248 oF)

1 hour at 130 oC (266 oF): 130 - 140 oC (266 - 284 oF)

10 min at 150 oC (302 oF): 130 - 150 oC (266 - 302 oF)

TYPICAL MECHANICAL PROPERTIES OF LAMINATE

Cured at 130 oC for 60 minutes and 3 bar

Flexural strength (Mpa): 850

Flexural modulus (Gpa): 54

Tensile strength (MPa): 550

Tensile modulus (GPa): 60

ILSS - Short Beam Shear (Mpa): 67

Tg (DSC) 20 oC / min: 128 oC

Please click on picture, for a closer view to the fabric's real size. To realize actual size with precision please observe the threads / cm feature mentioned above.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibremax Ltd reserves the right to make modifications on fabrics, change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request with roll serial number.

Intrastat Number for this product: 68151200..

1,476.72€

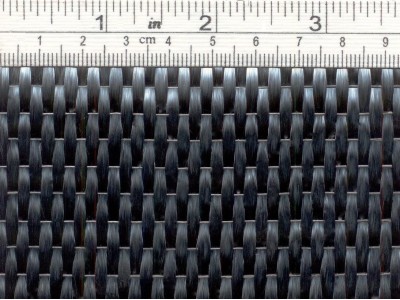

Carbon Prepreg C210Ppp, general purpose

TECHNICAL CHARACTERISTICS

Fabric weight: 205 g / sq.m.

Width: 1.00 meter

Prepreg weight: 394 g / sq.m.

Epoxy content: 42%

Gel time at 125 oC: 11 min

Volatile content: < 1 %

Weaving style: Plain

Warp: 3K TR30S carbon fiber, 50%, 5.25 ends(threads) / cm

Weft: 3K TR30S carbon fiber, 50%, 5.25 ends / cm

Fibermax general purpose prepregs are based on a 80 to 150 oC (176 - 302 oF) curing toughened epoxy matrix, suited for both autoclave and press molding applications. A standard autoclave curing cycle is: Draw vacuum (0.6 - 0.7 bar) and apply positive pressure. Then start heating - typically 2 - 5 oC / min (3.5 - 9 oF) - till 120 oC (248 oF) and then hold this temperature for 1 hour. Turn off the temperature and cool under pressure to 60 oC (140 oF). When fully cooled open the bag and extract the piece.

STORAGE LIFE

12 months at - 18 oC

4 - 6 weeks at room temperature

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

EVALUATED Tg FOR RESPECTIVE CURING CYCLE

1 hour at 120 oC (248 oF): 110 - 120 oC (230 - 248 oF)

1 hour at 130 oC (266 oF): 130 - 140 oC (266 - 284 oF)

10 min at 150 oC (302 oF): 130 - 150 oC (266 - 302 oF)

TYPICAL MECHANICAL PROPERTIES OF LAMINATE

(Cured at 130 oC for 60 minutes and 3 bar)

Flexural strength (Mpa): 850

Flexural modulus (Gpa): 54

Tensile strength (MPa): 550

Tensile modulus (GPa): 60

ILSS - Short Beam Shear (Mpa): 67

Tg (DSC) 20 oC / min: 128 oC

Please click on picture, for a closer view to the fabric's real size. To realize actual size with precision please observe the threads / cm feature mentioned above.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibremax Ltd reserves the right to make modifications on fabrics, change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request with roll serial number.

Intrastat Number for this product: 68151200..

From 40.53€ ...to 49.33€

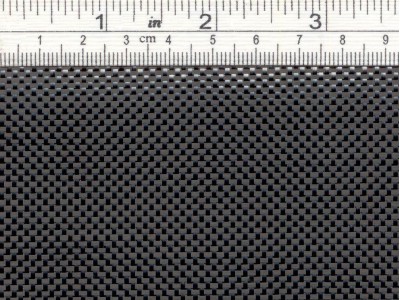

Carbon prepreg C210T2pp, general purpose

TECHNICAL CHARACTERISTICS

Fabric weight: 206 g / sq.m.

Width: 1.00 meter

Prepreg weight: 381 g / sq.m.

Epoxy content: 46 %

Gel time at 125 oC: 6-9 min

Volatile content: < 1 %

Weaving style: Twill 2X2

Warp: 3K TR30S carbon fiber, 49.5%, 5.10 ends (threads) / cm

Weft: 3K TR30S carbon fiber, 50.5%, 5.20 ends / cm

Fibermax general purpose prepregs are based on a 80 to 150 oC (176 - 302 oF) curing toughened epoxy matrix, suited for both autoclave and press molding applications. A standard autoclave curing cycle is: Draw vacuum (0.6 - 0.7 bar) and apply positive pressure. Then start heating - typically 2-5 oC / min (3.5 - 9 oF) - till 120 oC (248 oF) and then hold this temperature for 1 hour. Turn off the temperature and cool under pressure to 60 oC (140 oF). When fully cooled open the bag and extract the piece.

STORAGE LIFE

12 months at - 18 oC

4 - 6 weeks at room temperature

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

EVALUATED Tg FOR SUGGESTED CURING CYCLE

1 hour at 125 oC: 120 - 125 oC

2 hours at 110 oC: 120 - 125 oC

TYPICAL MECHANICAL PROPERTIES OF LAMINATE

Cured by hot press technology at 125°C curing cycle

Flexural strength (Mpa): 800

Flexural modulus (GPa): 54

ILSS - Short Beam Shear (Mpa): 64

Please click on picture, for a closer view to the fabric's real size. To realize actual size with precision please observe the threads / cm feature mentioned above.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibremax Ltd reserves the right to make modifications on fabrics, change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request with roll serial number.

Intrastat Number for this product: 68151200..

From 42.30€ ...to 51.10€

Carbon prepreg C211T2pp, optimized for hot press

TECHNICAL CHARACTERISTICS

Fabric weight: 206 g / sq.m.

Width: 1.00 meter

Prepreg weight: 381 g / sq.m.

Epoxy content: 46 %

Volatile content: < 1 %

Weaving style: Twill 2X2

Warp: 3K TR30S carbon fiber, 49.5%, 5.10 ends (threads) / cm

Weft: 3K TR30S carbon fiber, 50.5%, 5.20 ends / cm

RECOMMENDED CURING CYCLES

8 min at 150 C

10 min at 145 C

15 min at 140 C

STORAGE LIFE

12 months at - 18 oC

3 weeks at room temperature

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

Please click on picture, for a closer view to the fabric's real size. To realize actual size with precision please observe the threads / cm feature mentioned above.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibermax Composites reserves the right to make modifications on fabrics, change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request with roll serial number.

Intrastat Number for this product: 68151200..

From 42.30€ ...to 52.50€

Carbon prepreg C212T2pp, optimized for out of autoclave (vacuum only) curing. One side of the fabric is partially impregnated with a resin film, and the other side is dry (to facilitate the air and volatile content to escape). C212T2pp is a not high tack prepreg. Tack enhancing may be achieved by means of temperature or special purpose tack modification spray.

TECHNICAL CHARACTERISTICS

Fabric weight: 206 g / sq.m.

Width: 1.27 meters

Weaving style: Twill 2X2

Prepreg weight: 332 g / sq.m.

Epoxy content: 38 %

Volatile content: < 1 %

Gel time at 125 C: 7-8 min

Warp: 3K TR30S carbon fiber, 49.5%, 5.10 ends (threads) / cm

Weft: 3K TR30S carbon fiber, 50.5%, 5.20 ends / cm

RECOMMENDED CURING CYCLES

12 h at 80 C (Tg 110-115 C) or

1 h at 135 C (Tg 120-125 C)

RECOMMENDED PROCEDURE

Draw vacuum to evacuate entrapped air for at least 1 hour, depending on size and complexity of the mould

Raise temperature to 70 C

Keep 70 C for at least 1 hour, depending on the size and complexity of the mould

Raise temperature to 135 C, with a step of 1-3 C / min

Keep 135 C for about 1 hour, depending on number of layers, area size, complexity and type of mould

STORAGE LIFE

12 months at - 18 oC

5-6 weeks at room temperature

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

Please click on picture, for a closer view to the fabric's real size. To realize actual size with precision please observe the threads / cm feature mentioned above.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibremax Ltd reserves the right to make modifications on fabrics, change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request with roll serial number.

Intrastat Number for this product: 68151200..

From 48.15€ ...to 56.95€

Carbon prepreg C240T2pp, general purpose, 40 sq.m. roll

Price: 1908.00 EUR / 40 sq.m. roll

Price / sq.m.: 47.70 EUR

TECHNICAL CHARACTERISTICS

Fabric weight: 240 g / sq.m.

Width: 1.00 meter

Prepreg weight: 429 g / sq.m.

Epoxy content: 42 %

Gel time at 125 oC: 11 min

Volatile content: < 1 %

Weaving style: Twill 2X2

Warp: 3K T300 carbon fiber, 50%, 6 ends(threads) / cm

Weft: 3K T300 carbon fiber, 50%, 6 ends / cm

Fibermax general purpose prepregs are based on a 80 to 150 oC (176 - 302 oF) curing toughened epoxy matrix, suited for both autoclave and press molding applications. A standard autoclave curing cycle is: Draw vacuum (0.6 - 0.7 bar) and apply positive pressure. Then start heating - typically 2-5 oC / min (3.5 - 9 oF) - till 120 oC (248 oF) and then hold this temperature for 1 hour. Turn off the temperature and cool under pressure to 60 oC (140 oF). When fully cooled open the bag and extract the piece.

STORAGE LIFE

12 months at - 18 oC

4 - 6 weeks at room temperature

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

EVALUATED Tg FOR RESPECTIVE CURING CYCLE

1 hour at 120 oC (248 oF): 110 - 120 oC (230 - 248 oF)

1 hour at 130 oC (266 oF): 130 - 140 oC (266 - 284 oF)

10 min at 150 oC (302 oF): 130 - 150 oC (266 - 302 oF)

TYPICAL MECHANICAL PROPERTIES OF LAMINATE

Cured at 130 oC for 60 minutes and 3 bar

Flexural strength (Mpa): 850

Flexural modulus (Gpa): 54

Tensile strength (MPa): 550

Tensile modulus (GPa): 60

ILSS - Short Beam Shear (Mpa): 67

Tg (DSC) 20 oC / min: 128 oC

Please click on picture, for a closer view to the fabric's real size. To realize actual size with precision please observe the threads / cm feature mentioned above.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibremax Ltd reserves the right to make modifications on fabrics, change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request with roll serial number.

Intrastat Number for this product: 68151200..

1,908.00€

Carbon prepreg C242T2pp, optimized for out of autoclave (vacuum only) curing. One side of the fabric is partially impregnated with a resin film, and the other side is dry (to facilitate the air and volatile content to escape)

TECHNICAL CHARACTERISTICS

Fabric weight: 240 g / sq.m.

Weaving style: Twill 2X2

Width: 1.00 meter

Prepreg weight: 387 g / sq.m.

Epoxy content: 38 %

Volatile content: < 1 %

Gel time at 125 C: 7-8 min

Warp: 3K TR30S carbon fiber, 50%, 6 ends (threads) / cm

Weft: 3K TR30S carbon fiber, 50%, 6 ends / cm

RECOMMENDED CURING CYCLES

12 h at 80 C (Tg 110-115 C)

1 h at 135 C (Tg 120-125 C)

RECOMMENDED PROCEDURE

Draw vacuum to evacuate entraped air for at least 1 hour, depending on size and complexity of the mould

Raise temperature to 70 C

Keep 70 C for at least 1 hour, depending on the size and complexity of the mould

Raise temperature to 135 C, with a step of 1-3 C / min

Keep 135 C for about 1 hour, depending on number of layers, area size, complexity and type of mould

STORAGE LIFE

12 months at - 18 oC

5 weeks at room temperature

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

Please click on picture, for a closer view to the fabric's real size. To realize actual size with precision please observe the threads / cm feature mentioned above.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibremax Ltd reserves the right to make modifications on fabrics, change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request with roll serial number.

Intrastat Number for this product: 68151200..

From 52.02€ ...to 60.82€

Carbon prepreg C280T2pp, general purpose, 40 sq.m. roll

Price: 2136.00 EUR / 40 sq.m. roll

Price / sq.m.: 53.40 EUR

TECHNICAL CHARACTERISTICS

Fabric weight: 280 g / sq.m.

Width: 1.00 meter

Prepreg weight: 491 g / sq.m.

Epoxy content: 42 %

Gel time at 125 oC: 11 min

Volatile content: < 1 %

Weaving style: Twill 2X2

Warp: 6K T300 carbon fiber, 50%, 5.25 ends (threads) / cm

Weft: 6K T300 carbon fiber, 50%, 5.25 ends / cm

Fibermax general purpose prepregs are based on a 80 to 150 oC (176 - 302 oF) curing toughened epoxy matrix, suited for both autoclave and press molding applications. A standard autoclave curing cycle is: Draw vacuum (0.6 - 0.7 bar) and apply positive pressure. Then start heating - typically 2-5 oC / min (3.5 - 9 oF) - till 120 oC (248 oF) and then hold this temperature for 1 hour. Turn off the temperature and cool under pressure to 60 oC (140 oF). When fully cooled open the bag and extract the piece.

STORAGE LIFE

12 months at - 18 oC

4 - 6 weeks at room temperature

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

EVALUATED Tg FOR RESPECTIVE CURING CYCLE

1 hour at 120 oC (248 oF): 110 - 120 oC (230 - 248 oF)

1 hour at 130 oC (266 oF): 130 - 140 oC (266 - 284 oF)

10 min at 150 oC (302 oF): 130 - 150 oC (266 - 302 oF)

TYPICAL MECHANICAL PROPERTIES OF LAMINATE

Cured at 130 oC for 60 minutes and 3 bar

Flexural strength (Mpa): 850

Flexural modulus (Gpa): 52

Tensile strength (MPa): 730

Tensile modulus (GPa): 62

ILSS - Short Beam Shear (Mpa): 66

Tg (DSC) 20 oC / min: 128 oC

Please click on picture, for a closer view to the fabric's real size. To realize actual size with precision please observe the threads / cm feature mentioned above.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibremax Ltd reserves the right to make modifications on fabrics, change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request with roll serial number.

Intrastat Number for this product: 68151200..

2,136.00€

Carbon prepreg C285T2pp, general purpose, 40 sq.m. roll

Price: 2124.00 EUR / 40 sq.m. roll

Price / sq.m.: 53.10 EUR

TECHNICAL CHARACTERISTICS

Fabric weight: 285 g / sq.m.

Width: 1.00 meter

Prepreg weight: 500 g / sq.m.

Epoxy content: 42 %

Gel time at 125 oC: 11 min

Volatile content: < 1 %

Weaving style: Twill 2X2

Warp: 3K T300 carbon fiber, 50%, 7 ends(threads) / cm

Weft: 3K T300 carbon fiber, 50%, 7 ends / cm

Fibermax general purpose prepregs are based on a 80 to 150 oC (176 - 302 oF) curing toughened epoxy matrix, suited for both autoclave and press molding applications. A standard autoclave curing cycle is: Draw vacuum (0.6 - 0.7 bar) and apply positive pressure. Then start heating - typically 2-5 oC / min (3.5 - 9 oF) - till 120 oC (248 oF) and then hold this temperature for 1 hour. Turn off the temperature and cool under pressure to 60 oC (140 oF). When fully cooled open the bag and extract the piece.

STORAGE LIFE

12 months at - 18 oC

4 - 6 weeks at room temperature

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

EVALUATED Tg FOR RESPECTIVE CURING CYCLE

1 hour at 120 oC (248 oF): 110 - 120 oC (230 - 248 oF)

1 hour at 130 oC (266 oF): 130 - 140 oC (266 - 284 oF)

10 min at 150 oC (302 oF): 130 - 150 oC (266 - 302 oF)

TYPICAL MECHANICAL PROPERTIES OF LAMINATE

Cured at 130 oC for 60 minutes and 3 bar

Flexural strength (Mpa): 850

Flexural modulus (Gpa): 54

Tensile strength (MPa): 550

Tensile modulus (GPa): 60

ILSS - Short Beam Shear (Mpa): 67

Tg (DSC) 20 oC / min: 128 oC

Please click on picture, for a closer view to the fabric's real size. To realize actual size with precision please observe the threads / cm feature mentioned above.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibremax Ltd reserves the right to make modifications on fabrics, change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request with roll serial number.

Intrastat Number for this product: 68151200..

2,124.00€

Carbon prepreg C285T4pp, general purpose

TECHNICAL CHARACTERISTICS

Fabric weight: 285 g / sq.m.

Width: 1.00 meter

Prepreg weight: 510 g / sq.m.

Epoxy content: 44%

Gel time at 125 oC: 6-9 min

Volatile content: < 1 %

Weaving style: Twill 4X4

Warp: 3K T300 carbon fiber, 50%, 7 ends(threads) / cm

Weft: 3K T300 carbon fiber, 50%, 7 ends / cm

Fibermax general purpose prepregs are based on a 80 to 150 oC (176 - 302 oF) curing toughened epoxy matrix, suited for both autoclave and press molding applications. A standard autoclave curing cycle is: Draw vacuum (0.6 - 0.7 bar) and apply positive pressure. Then start heating - typically 2-5 oC / min (3.5 - 9 oF) - till 120 oC (248 oF) and then hold this temperature for 1 hour. Turn off the temperature and cool under pressure to 60 oC (140 oF). When fully cooled open the bag and extract the piece.

STORAGE LIFE

12 months at - 18 oC

5 weeks at room temperature

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

EVALUATED Tg FOR SUGGESTED CURING CYCLE

1 hour at 125 oC: 120 - 125 oC

2 hours at 110 oC: 120 - 125 oC

TYPICAL MECHANICAL PROPERTIES OF LAMINATE

Cured by hot press technology at 125°C curing cycle

Flexural strength (Mpa): 805

Flexural modulus (Gpa): 51

ILSS - Short Beam Shear (Mpa): 61

Please click on picture, for a closer view to the fabric's real size. To realize actual size with precision please observe the threads / cm feature mentioned above.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibremax Ltd reserves the right to make modifications on fabrics, change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request with roll serial number.

Intrastat Number for this product: 68151200..

From 53.10€ ...to 61.90€

Carbon prepreg C330Upp, general purpose

TECHNICAL CHARACTERISTICS

Fabric weight: 324 g / sq.m.

Width: 1.00 meter

Prepreg weight: 540 g / sq.m.

Epoxy content: 40%

Gel time at 125 oC: 6-9 min

Volatile content: < 1 %

Weaving style: Unidirectional

Warp: HTS 45 E23 12K carbon fiber, 93.33%, 3.80 ends (threads) / cm

Weft: E Glass EC9 68tex, 6.67%, 3.00 ends / cm

Fibermax general purpose prepregs are based on a 80 to 150 oC (176 - 302 oF) curing toughened epoxy matrix, suited for both autoclave and press molding applications. A standard autoclave curing cycle is: Draw vacuum (0.6 - 0.7 bar) and apply positive pressure. Then start heating - typically 2-5 oC / min (3.5 - 9 oF) - till 120 oC (248 oF) and then hold this temperature for 1 hour. Turn off the temperature and cool under pressure to 60 oC (140 oF). When fully cooled open the bag and extract the piece.

STORAGE LIFE

12 months at - 18 oC

5 weeks at room temperature

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

EVALUATED Tg FOR SUGGESTED CURING CYCLE

1 hour at 125 oC: 120 - 125 oC

2 hours at 110 oC: 120 - 125 oC

TYPICAL MECHANICAL PROPERTIES OF LAMINATE

Cured by hot press technology at 125°C curing cycle

Flexural strength (Mpa): 1150

Flexural modulus (Gpa): 115

ILSS - Short Beam Shear (Mpa): 73

Please click on picture, for a closer view to the fabric's real size. To realize actual size with precision please observe the threads / cm feature mentioned above.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibremax Ltd reserves the right to make modifications on fabrics, change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request with roll serial number.

Intrastat Number for this product: 68151200..

From 38.16€ ...to 46.96€

Carbon prepreg C420Upp, general purpose, 40 sq.m. roll

Price: 1716.96 EUR / 40 sq.m. roll

Price / sq.m.: 42.92 EUR

TECHNICAL CHARACTERISTICS

Fabric weight: 420 g / sq.m.

Width: 1.00 meter

Prepreg weight: 680 g / sq.m.

Epoxy content: 38 %

Gel time at 125 oC: 11 min

Volatile content: < 1 %

Weaving style: Unidirectional, woven

Warp: 12K TR50S carbon fiber, 92%, 5.00 ends(threads) / cm

Weft: Glass thermoplastic 8%, 1.60 ends(threads) / cm

Fibermax general purpose prepregs are based on a 80 to 150 oC (176 - 302 oF) curing toughened epoxy matrix, suited for both autoclave and press molding applications. A standard autoclave curing cycle is: Draw vacuum (0.6 - 0.7 bar) and apply positive pressure. Then start heating - typically 2-5 oC / min (3.5 - 9 oF) - till 120 oC (248 oF) and then hold this temperature for 1 hour. Turn off the temperature and cool under pressure to 60 oC (140 oF). When fully cooled open the bag and extract the piece.

STORAGE LIFE

12 months at - 18 oC

4 - 6 weeks at room temperature

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

EVALUATED Tg FOR RESPECTIVE CURING CYCLE

1 hour at 120 oC (248 oF): 110 - 120 oC (230 - 248 oF)

1 hour at 130 oC (266 oF): 130 - 140 oC (266 - 284 oF)

10 min at 150 oC (302 oF): 130 - 150 oC (266 - 302 oF)

TYPICAL MECHANICAL PROPERTIES OF LAMINATE

Cured at 130 oC for 60 minutes and 3 bar

Flexural strength (Mpa): 850

Flexural modulus (Gpa): 59

Tensile strength (MPa): 650

Tensile modulus (GPa): 59

ILSS - Short Beam Shear (Mpa): 65

Tg (DSC) 20 oC / min: 140 oC

Please click on picture, for a closer view to the fabric's real size. To realize actual size with precision please observe the threads / cm feature mentioned above.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibremax Ltd reserves the right to make modifications on fabrics, change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request with roll serial number.

Intrastat Number for this product: 68151200..

1,716.96€

Carbon prepreg C428T2pp, general purpose

TECHNICAL CHARACTERISTICS

Fabric weight: 428 g / sq.m.

Width: 1.00 meter

Prepreg weight: 740 g / sq.m.

Epoxy content: 42 %

Gel time at 125 oC: 6-9 min

Volatile content: < 1 %

Weaving style: Twill 2X2

Warp: 12K T700 carbon fiber, 50%, 2.7 ends (threads) / cm

Weft: 12K T700 carbon fiber, 50%, 2.7 ends / cm

Fibermax general purpose prepregs are based on a 80 to 150 oC (176 - 302 oF) curing toughened epoxy matrix, suited for both autoclave and press molding applications. A standard autoclave curing cycle is: Draw vacuum (0.6 - 0.7 bar) and apply positive pressure. Then start heating - typically 2-5 oC / min (3.5 - 9 oF) - till 120 oC (248 oF) and then hold this temperature for 1 hour. Turn off the temperature and cool under pressure to 60 oC (140 oF). When fully cooled open the bag and extract the piece.

STORAGE LIFE

12 months at - 18 oC

5 weeks at room temperature

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

EVALUATED Tg FOR SUGGESTED CURING CYCLE

1 hour at 125 oC: 120 - 125 oC

2 hours at 110 oC: 120 - 125 oC

TYPICAL MECHANICAL PROPERTIES OF LAMINATE

Cured by hot press technology at 125°C curing cycle

Flexural strength (Mpa): 800

Flexural modulus (Gpa): 52

ILSS - Short Beam Shear (Mpa): 64

Please click on picture, for a closer view to the fabric's real size. To realize actual size with precision please observe the threads / cm feature mentioned above.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibremax Ltd reserves the right to make modifications on fabrics, change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request with roll serial number.

Intrastat Number for this product: 68151200..

From 44.55€ ...to 53.35€

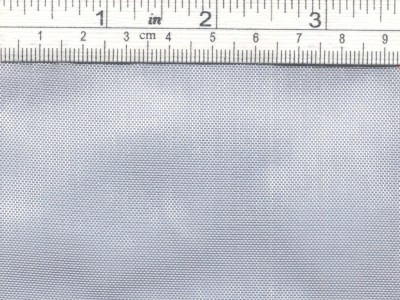

Fiberglass prepreg G050Ppp, general purpose

TECHNICAL CHARACTERISTICS

Fabric weight: 46 g / sq.m.

Width: 1.00 meter

Prepreg weight: 115 g / sq.m.

Epoxy content: 60%

Gel time at 125 oC: 11 min

Volatile content: < 1 %

Weaving style: Plain

Warp: Glass EC5 11 fiber, 56%, 22 ends (threads) / cm

Weft: Glass EC5 11 fiber, 44%, 22 ends / cm

Fibermax general purpose prepregs are based on a 80 to 150 oC (176 - 302 oF) curing toughened epoxy matrix, suited for both autoclave and press molding applications. A standard autoclave curing cycle is: Draw vacuum (0.6 - 0.7 bar) and apply positive pressure. Then start heating - typically 2-5 oC / min (3.5 - 9 oF) - till 120 oC (248 oF) and then hold this temperature for 1 hour. Turn off the temperature and cool under pressure to 60 oC (140 oF). When fully cooled open the bag and extract the piece.

STORAGE LIFE

12 months at - 18 oC

4 - 6 weeks at room temperature

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

EVALUATED Tg FOR RESPECTIVE CURING CYCLE

1 hour at 120 oC (248 oF): 110 - 120 oC (230 - 248 oF)

1 hour at 130 oC (266 oF): 130 - 140 oC (266 - 284 oF)

10 min at 150 oC (302 oF): 130 - 150 oC (266 - 302 oF)

TYPICAL MECHANICAL PROPERTIES OF LAMINATE

Cured at 130 oC for 60 minutes and 3 bar

Flexural strength (Mpa): 850

Flexural modulus (Gpa): 54

Tensile strength (MPa): 550

Tensile modulus (GPa): 60

ILSS - Short Beam Shear (Mpa): 67

Tg (DSC) 20 oC / min: 128 oC

Please click on picture, for a closer view to the fabric's real size. To realize actual size with precision please observe the threads / cm feature mentioned above.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibremax Ltd reserves the right to make modifications on fabrics, change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request with roll serial number.

Intrastat Number for this product: 68151200..

From 14.62€ ...to 19.50€

Adhesive film F180Vpp, suitable for vacuum bag, press or autoclave process, based on preimpregnated ultralight supporting veil (to ease handling)

TECHNICAL CHARACTERISTICS

Supporting veil nominal weight: 14 g/sq.m. (8%)

Resin weight: 166 g/sq.m. (92%)

Total prepreg weight: 180 g/sq.m.

Volatile content: < 1.5 %

Gel time at 125 C: 7 min

RECOMMENDED CURING CYCLES

16 h at 80 C (Tg 90 C) - postcuring at 125 C recommended

9 h at 90 C (Tg 100 C) - postcuring at 125 C recommended

5 h at 100 C (Tg 110 C) - postcuring at 125 C recommended

1 h at 120 C (Tg 120 C)

Postcuring at 130 C (with a step of 1 C/min) could be performed in order to maximize properties

STORAGE LIFE

12 months at - 18 oC

5 weeks at 20 C

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

Please click on picture, for a closer view to the fabric's real size. To realize actual size with precision please observe the threads / cm feature mentioned above.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibermax Composites reserves the right to make modifications on fabrics, change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request with roll serial number.

Intrastat Number for this product: 68151200..

From 27.21€ ...to 36.57€

Showing 1 to 17 of 17 (1 Pages)

-400x300w.jpg)

-400x300w.jpg)

-400x300w.jpg)