30.12 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 2 mm

Panel size: 950 X 2050 mm

Total surface of 1 panel: 1.95 m2

CELLFOAM

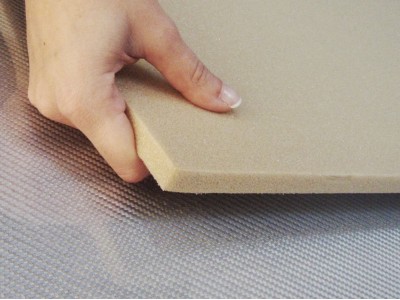

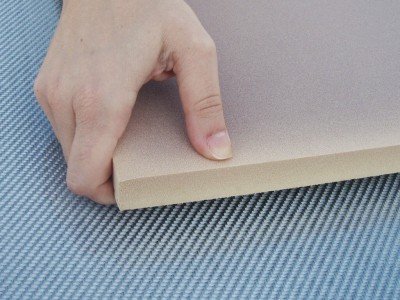

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

30.12€

23.86 EUR / panel

Spec. weight: 60 kg / m3

Thickness: 3 mm

Panel size: 1150 X 2450 mm

Total surface of 1 panel: 2.82 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

23.86€

29.26 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 3 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

29.26€

31.87 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 3 mm

Panel size: 950 X 2050 mm

Total surface of 1 panel: 1.95 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

31.87€

39.13 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 5 mm

Panel size: 950 X 2050 mm

Total surface of 1 panel: 1.95 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

39.13€

39.14 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 7 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

39.14€

44.73 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 8 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

44.73€

47.97 EUR / panel

Spec. weight: 60 kg / m3

Thickness: 10 mm

Panel size: 1150 X 2450 mm

Total surface of 1 panel: 2.82 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

47.97€

55.92 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 10 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

55.92€

29.43 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 10 mm

Panel size: 1090 X 1020 mm

Total surface of 1 panel: 1.11 m2

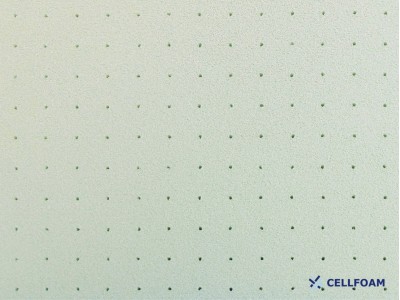

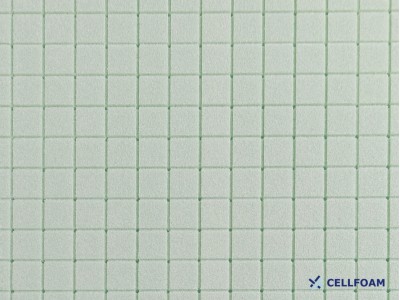

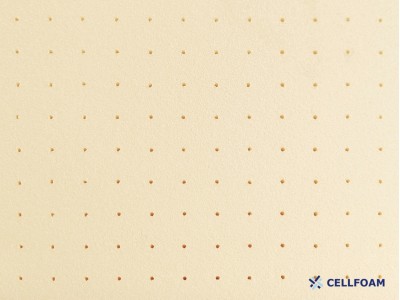

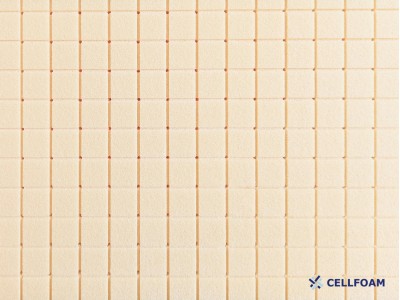

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

29.43€

58.15 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 10 mm

Panel size: 950 X 2050 mm

Total surface of 1 panel: 1.95 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

58.15€

54.82 EUR / panel

Spec weight: 60 kg / m3

Thickness: 12 mm

Panel size: 1150 X 2450 mm

Total surface of 1 panel: 2.82 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

54.82€

64.24 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 12 mm

Panel size: 1000 X 2150mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

64.24€

69.78 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 12 mm

Panel size: 950 X 2050 mm

Total surface of 1 panel: 1.95 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

69.78€

66.80 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 13 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

66.80€

67.84 EUR / panel

Spec weight: 60 kg / m3

Thickness: 15 mm

Panel size: 1150 X 2450 mm

Total surface of 1 panel: 2.82 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

67.84€

76.63 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 15 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

76.63€

40.35 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 15 mm

Panel size: 1090 X 1020 mm

Total surface of 1 panel: 1.11 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

40.35€

76.33 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 15 mm

Panel size: 950 X 2050 mm

Total surface of 1 panel: 1.95 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

76.33€

61.27 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 15 mm

Panel size: 960 X 1330 mm

Total surface of 1 panel: 1.28 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

61.27€

82.79 EUR / panel

Spec weight: 60 kg / m3

Thickness: 20 mm

Panel size: 1150 X 2450 mm

Total surface of 1 panel: 2.82 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

82.79€

92.30 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 20 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

92.30€

48.59 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 20 mm

Panel size: 1090 X 1020 mm

Total surface of 1 panel: 1.11 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

48.59€

52.35 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 20 mm

Panel size: 1000 X 1070 mm

Total surface of 1 panel: 1.07 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

The HT type is suitable for high temperature applications. For example, it can be used for autoclave prepreg sandwich curing at 120°C and 3 bar pressure. Higher temperature and pressure applications are possible, depending on the tolerance for potential partial collapse (collapse refers to a reduction in thickness without implying a loss of mechanical properties).

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

52.35€

96.78 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 20 mm

Panel size: 950 X 2050 mm

Total surface of 1 panel: 1.95 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

96.78€

149.03 EUR / panel

Spec. weight: 200 kg / m3

Thickness: 20 mm

Panel size: 700 X 1500 mm

Total surface of 1 panel: 1.05 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

149.03€

112.62 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 25 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

112.62€

59.30 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 25 mm

Panel size: 1090 X 1020 mm

Total surface of 1 panel: 1.11 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed cell PVC foam with holes and grooves for infusion. Holes allow the resin to pass easily through the foam while the grooves on the underside act to distribute the resin and aid flow on the underside. Its excellent stiffness, strength to weight ratio, and high toughness make it suitable for a large variety of applications. It can be shaped with wood tools, sandpaper and can be thermoformed to curves. The foam is ideally suited for statically and dynamically loaded structures and is compatible to all resin systems.

Main characteristics:

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

59.30€

62.46 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 25 mm

Panel size: 1000 X 1070 mm

Total surface of 1 panel: 1.07 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

The HT type is suitable for high temperature applications. For example, it can be used for autoclave prepreg sandwich curing at 120°C and 3 bar pressure. Higher temperature and pressure applications are possible, depending on the tolerance for potential partial collapse (collapse refers to a reduction in thickness without implying a loss of mechanical properties).

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

62.46€

124.41 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 25 mm

Panel size: 950 X 2050 mm

Total surface of 1 panel: 1.95 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

124.41€

183.42 EUR / panel

Spec. weight: 200 kg / m3

Thickness: 25 mm

Panel size: 750 X 1600 mm

Total surface of 1 panel: 1.20 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

183.42€

111.36 EUR / panel

Spec. weight: 60 kg / m3

Thickness: 30 mm

Panel size: 1150 X 2450 mm

Total surface of 1 panel: 2.82 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

111.36€

131.39 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 30 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

131.39€

69.18 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 30 mm

Panel size: 1090 X 1020 mm

Total surface of 1 panel: 1.11 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

69.18€

71.80 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 30 mm

Panel size: 1000 X 1070 mm

Total surface of 1 panel: 1.07 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

The HT type is suitable for high temperature applications. For example, it can be used for autoclave prepreg sandwich curing at 120°C and 3 bar pressure. Higher temperature and pressure applications are possible, depending on the tolerance for potential partial collapse (collapse refers to a reduction in thickness without implying a loss of mechanical properties).

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

71.80€

135.00 EUR / panel

Spec. weight: 60 kg / m3

Thickness: 40 mm

Panel size: 1150 X 2450 mm

Total surface of 1 panel: 2.82 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

135.00€

163.12 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 40 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

163.12€

87.59 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 40 mm

Panel size: 1000 X 1070 mm

Total surface of 1 panel: 1.07 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

The HT type is suitable for high temperature applications. For example, it can be used for autoclave prepreg sandwich curing at 120°C and 3 bar pressure. Higher temperature and pressure applications are possible, depending on the tolerance for potential partial collapse (collapse refers to a reduction in thickness without implying a loss of mechanical properties).

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

87.59€

186.64 EUR / panel

Spec weight: 60 kg / m3

Thickness: 50 mm

Panel size: 1150 X 2450 mm

Total surface of 1 panel: 2.82 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

186.64€

201.86 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 50 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

201.86€

106.87 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 50 mm

Panel size: 1000 X 1070 mm

Total surface of 1 panel: 1.07 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

The HT type is suitable for high temperature applications. For example, it can be used for autoclave prepreg sandwich curing at 120°C and 3 bar pressure. Higher temperature and pressure applications are possible, depending on the tolerance for potential partial collapse (collapse refers to a reduction in thickness without implying a loss of mechanical properties).

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

106.87€

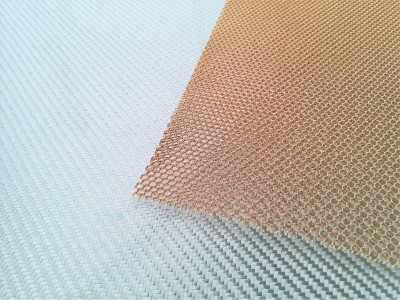

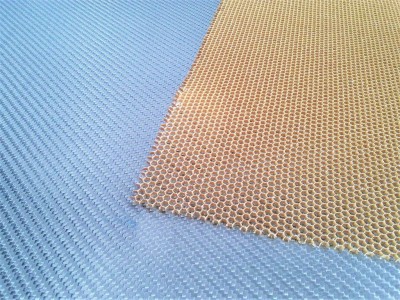

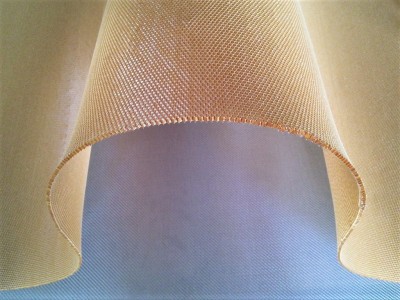

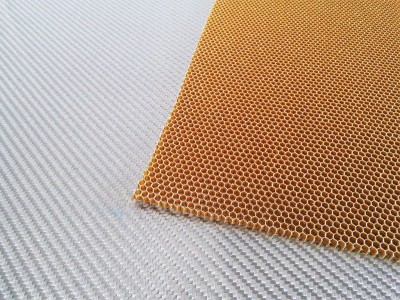

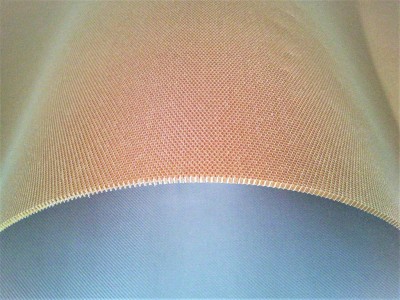

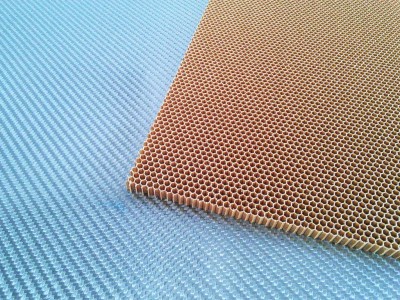

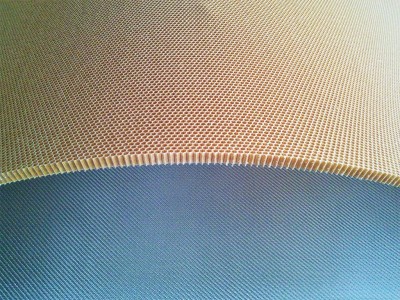

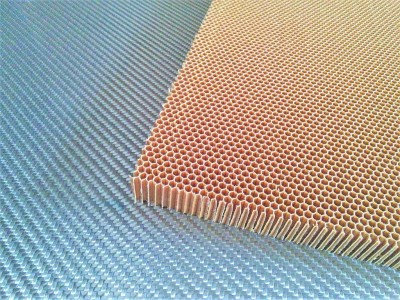

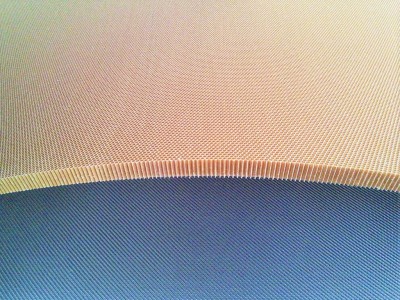

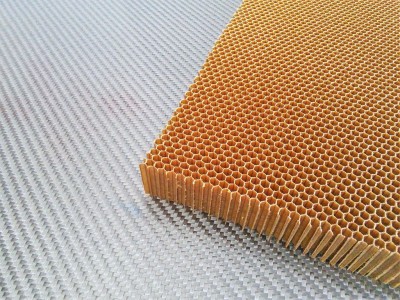

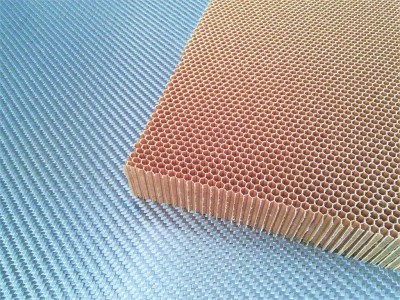

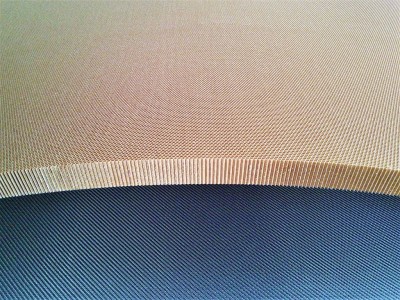

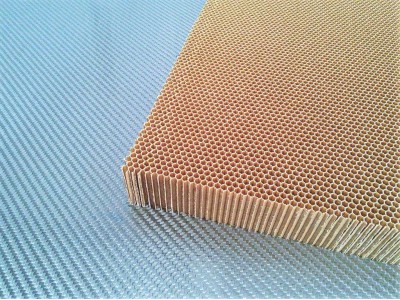

Aramid honeycomb, Nomex or equivalent

79.10 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 1.5 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 300 PSI

Modulus: 18.5 KSI

Plate shear:

Strength (PSI "L" direc): 160

Strength (PSI "W" direc): 90

Modulus (KSI "L" direc): 5.3

Modulus (KSI "W" direc): 3.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

79.10€

123.00 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 50 mm

Panel size: 950 X 1025 mm

Total surface of 1 panel: 0.97 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

123.00€

Aramid honeycomb Nomex or equivalent

90.42 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 2 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 300 PSI

Modulus: 18.5 KSI

Plate shear:

Strength (PSI "L" direc): 160

Strength (PSI "W" direc): 90

Modulus (KSI "L" direc): 5.3

Modulus (KSI "W" direc): 3.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

90.42€

Aramid honeycomb Nomex or equivalent

113.05 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 3 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 300 PSI

Modulus: 18.5 KSI

Plate shear:

Strength (PSI "L" direc): 160

Strength (PSI "W" direc): 90

Modulus (KSI "L" direc): 5.3

Modulus (KSI "W" direc): 3.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

113.05€

Aramid honeycomb Nomex or equivalent

135.70 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 4 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 300 PSI

Modulus: 18.5 KSI

Plate shear:

Strength (PSI "L" direc): 160

Strength (PSI "W" direc): 90

Modulus (KSI "L" direc): 5.3

Modulus (KSI "W" direc): 3.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

135.70€

Aramid honeycomb, Nomex or equivalent

158.04 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 5 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 300 PSI

Modulus: 18.5 KSI

Plate shear:

Strength (PSI "L" direc): 160

Strength (PSI "W" direc): 90

Modulus (KSI "L" direc): 5.3

Modulus (KSI "W" direc): 3.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

158.04€

Aramid honeycomb, Nomex or equivalent

203.49 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 7 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 150 PSI

Modulus: 11 KSI

Plate shear:

Strength (PSI "L" direc): 100

Strength (PSI "W" direc): 55

Modulus (KSI "L" direc): 4.3

Modulus (KSI "W" direc): 2.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

203.49€

Aramid honeycomb, Nomex or equivalent

268.75 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 10 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 300 PSI

Modulus: 18.5 KSI

Plate shear:

Strength (PSI "L" direc): 160

Strength (PSI "W" direc): 90

Modulus (KSI "L" direc): 5.3

Modulus (KSI "W" direc): 3.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

268.75€

Aramid honeycomb, Nomex or equivalent

384.34 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 15 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 150 PSI

Modulus: 11 KSI

Plate shear:

Strength (PSI "L" direc): 100

Strength (PSI "W" direc): 55

Modulus (KSI "L" direc): 4.3

Modulus (KSI "W" direc): 2.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

384.34€

Aramid honeycomb, Nomex or equivalent

497.28 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 20 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 150 PSI

Modulus: 11 KSI

Plate shear:

Strength (PSI "L" direc): 100

Strength (PSI "W" direc): 55

Modulus (KSI "L" direc): 4.3

Modulus (KSI "W" direc): 2.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

497.28€

Aramid honeycomb, Nomex or equivalent

610.35 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 25 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 150 PSI

Modulus: 11 KSI

Plate shear:

Strength (PSI "L" direc): 100

Strength (PSI "W" direc): 55

Modulus (KSI "L" direc): 4.3

Modulus (KSI "W" direc): 2.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

610.35€

Aramid honeycomb, Nomex or equivalent

723.32 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 30 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 150 PSI

Modulus: 11 KSI

Plate shear:

Strength (PSI "L" direc): 100

Strength (PSI "W" direc): 55

Modulus (KSI "L" direc): 4.3

Modulus (KSI "W" direc): 2.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

723.32€

Aramid honeycomb, Nomex or equivalent

964.43 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 40 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 150 PSI

Modulus: 11 KSI

Plate shear:

Strength (PSI "L" direc): 100

Strength (PSI "W" direc): 55

Modulus (KSI "L" direc): 4.3

Modulus (KSI "W" direc): 2.1