Flexible epoxy system SR8160 / SD815B4 with slow hardener

Each kilo includes 0.83 kg resin + 0.17 kg hardener

SR8160 / SD815B4 is a system designed for laminating parts that exhibit shock and impact resistance, like the underbody of off road car racing. It may be used alone or as an additive to modify other epoxy systems. Also, it may be used to impregnate the outer layer(s) of laminates (so to take first contact of impacts,) and to achieve anisotropic behavior (in terms of thickness) of a part. In this case special care should be taken so to prevent delamination by making a gradual transition from elastic to rigid matrix. This gradual transition can be achieved by using 2 or 3 progressively lower content ratios (on subsequent fabric layers) of SR8160 system, so to go from pure elastic to more rigid epoxy gradually. A very high ambient temperature is needed for pure SR8160 flexible system to start the hardening reaction.

Description:

- 80 to 110 % of elongation at break in tension

- Shock resistance over 150 KJ / m2

- Unfilled and translucent

- Advantages compared to polyurethane:

Does not foam when in contact with humidity

Memory of shape

Applications:

- Parts under vibrations, shocks, low temperature

- Flexible laminates: Body parts for cars, motorbike, 4X4 etc

- Casting and inclusion (degassing under vacuum)

- Part design / prototyping

Minimum curing cycle:

24 hours at ambient temperature + 6 hours at 40 oC + 10 hours at 60 oC

PROPERTIES

Physical properties of SR8160 epoxy resin:

Aspect / colour: Yellowish viscous liquid

Viscosity at 20 oC (mPa.s): 7800

Density at 20 oC (kg / l): 1.144

Physical properties of SD815B4 hardener:

Aspect / colour: Clear liquid

Viscosity at 20 oC (mPa.s): 24

Density at 20 oC (kg / l): 0.98

Mix properties of SR8160 / SD815B4 system:

Mix viscosities at 20 oC (m.Pas +- 20 %): 2750

Weight ratio: 100 / 20 g

Volume ratio: 100 / 24 ml

Reactivity of SR8160 / SD815B4 system:

Time taken to achieve exotherm at 30 oC: 4h

Intrastat Number for this product: Epoxy: 39073000, Hardener: 29213091..

From 42.72€ ...to 66.21€

Heat resistant epoxy system SR1660 / SD7820 with slow hardener

Each kilo includes 0.76 kg resin + 0.24 kg hardener

Epoxy system developed for high service temperature tooling from 120°C up to over 200°C continuously depending on the chosen hardener. It exhibits excellent chemical resistance, resistance to oxidization and low exothermic peak. Suitable for laminating, press moulding, casting or injection.

Slow hardener SD7820:

Epoxy system for parts or tooling with a service temperature up to 120°C, 160°C peak.

Applications:

Composite tooling for "120°C" prepreg, thermoforming tooling or structural parts with a high service temperature.

PROPERTIES

Physical properties of SR1660 epoxy resin:

Aspect / colour: Yellow liquid

Viscosity (m.Pas) at 20 oC / 68 oF: 8500 ± 1500

Density at 20 oC / 68 oF: 1.15 ± 0.01

Physical properties of SD7820 hardener:

Aspect / colour: Clear to yellow liquid

Viscosity (m.Pas) at 20 oC / 68 oF: 80 ± 15

Density (g/cm3): 0.96 ± 0.01

Mix properties of SR1660 / SD7820 system:

Weight ratio: 100 / 32 g

Volume ratio: 100 / 39 ml

Mix viscosity (m.Pas) at 20 oC / 68 oF: 2400 ± 500

Reactivity of SR1660 / SD7820 system:

Exothermic peak on 500 g mix (oC) at 20 oC:180 oC

Time to reach exothermic peak at 20 oC / 68 oF: 6 h

Intrastat Number for this product: Epoxy: 39073000, Hardener: 29213091..

From 20.00€ ...to 31.01€

Heat resistant epoxy system SR1660 / SD1305 with ultra slow hardener

Each kilo includes 0.76 kg resin + 0.24 kg hardener

Epoxy system developed for high service temperature tooling from 120°C up to over 200°C continuously depending on the chosen hardener. It exhibits excellent chemical resistance, resistance to oxidization and low exothermic peak. Suitable for laminating, press moulding, casting or injection.

Ultra slow hardener SD1305:

Epoxy system for parts or tooling with a service temperature up to 140°C, 180°C peak.

Applications:

Composite tooling for “140°C” prepreg, thermoforming tooling or structural parts with a high service temperature.

PROPERTIES

Physical properties of SR1660 epoxy resin:

Aspect / colour: Yellow liquid

Viscosity (m.Pas) at 20 oC / 68 oF: 8500 ± 1500

Density at 20 oC / 68 oF: 1.15 ± 0.01

Physical properties of SD1305 hardener:

Aspect / colour: Dark yellow liquid

Viscosity (m.Pas) at 20 oC / 68 oF: 278 ± 50

Density (g/cm3): 0.991 ± 0.01

Mix properties of SR1660 / SD1305 system:

Weight ratio: 100 / 32 g

Volume ratio: 100 / 39 ml

Mix viscosity (m.Pas) at 20 oC / 68 oF: 4000 ± 800

Reactivity of SR1660 / SD1305 system:

Exothermic peak on 500 g mix (oC) at 40 oC: 85 oC

Time to reach exothermic peak at 40 oC: 2 h

Intrastat Number for this product: Epoxy: 39073000, Hardener: 29213091..

From 22.35€ ...to 34.63€

Fire resistant epoxy laminating system SR1126 / SD8203 with medium hardener

Each kilo includes 0.83 kg resin + 0.17 kg hardener

Auto extinguishing laminating epoxy system. It creates low smokes and low toxicity smokes, exhibits good temperature resistance and is bromine free. With high temperature or fire, the system expands, producing solid char barrier that protects inner materials from heat and flames. This system allows to get UL94 V0 and FAR 25 laminate parts as well as AIRBUS and BOEING standards concerning fumes and fume toxicity (please see data sheet for all details concerning FAR 25 and UL94 V0 approvals).

Medium hardener SD8203:

Suitable for manufacturing medium to large part by hand lay, press moulding and vacuum bagging. Post cure at 40 °C minimum before unmoulding. Designed for high performance composites, with service temperature up to 60-70 °C.

PROPERTIES

Physical properties of SR1126 epoxy resin:

Aspect / colour: White viscous liquid

Viscosity (mPa.s) at 20 oC: 9 000 ± 2 000

Density at 20 oC / 68 oF: 1.28 ± 0.01

Physical properties of SD8203 hardener:

Aspect / colour: Yellow liquid

Viscosity (mPa.s) at 20 oC / 68 oF: 140 ± 30

Density (g/cm3) at 20 oC / 68 oF: 1.040 ± 0.005

Mix properties of SR1126 / SD8203 system:

Weight ratio: 100 / 20 g

Volume ratio: 100 / 26 ml

Mix viscosity at 20 oC / 68 oF: 2100 ± 400

Reactivity of SR1126 / SD8203 system:

Exothermic peak (°C) on 150 g mix at 20 oC: 42

Time to reach exothermic peak on 150 g mix at 20 oC: 3 h

Intrastat Number for this product: Epoxy: 39073000, Hardener: 29213091..

From 26.33€ ...to 40.81€

Fire resistant epoxy laminating system SR1126 / SD1305 with ultra slow hardener

Each kilo includes 0.85 kg resin + 0.15 kg hardener

Auto extinguishing laminating epoxy system. It creates low smokes and low toxicity smokes. It exhibits good temperature resistance and is bromine free. With high temperature or fire, the system expands, producing solid char barrier that protects inner materials from heat and flames. This system allows to get UL94 V0 and FAR 25 laminate parts as well as AIRBUS and BOEING standards concerning fumes and fume toxicity (please see data sheet for all details concerning FAR 25 and UL94 V0 approvals).

Ultra slow hardener SD1305:

Suitable for large parts, long pot life and hot process. Tg – onset / DSC = 130 °C. Post cure at 120 °C minimum

PROPERTIES

Physical properties of SR1126 epoxy resin

Aspect / colour: White viscous liquid

Viscosity (mPa.s) at 15 oC: 15000 ± 3000

Density at 20 oC / 68 oF: 1.28 ± 0.01

Physical properties of SD1305 hardener

Aspect / colour: Yellow to red liquid

Viscosity (mPa.s) at 20 oC / 68 oF: 278 ± 50

Density (g/cm3) at 20 oC / 68 oF: 0.990 ± 0.005

Mix properties of SR1126 / SD1305 system

Weight ratio: 100 / 18 g

Volume ratio: 100 / 23 ml

Mix viscosity at 20 oC / 68 oF: 4200 ± 800

Intrastat Number for this product: Epoxy: 39073000, Hardener: 29213091..

From 29.24€ ...to 45.32€

High temperature epoxy system SR1710 / SD7820

Each kilo includes 0.73 kg resin + 0.27 kg hardener

High temperature epoxy system specially formulated for oven temperature or autoclave conditions curing. It is used for production of high performance and high temperature resistant parts with outstanding mechanical properties in sectors such as motorsport, aerospace, and many more. It is also used for manufacturing of temperature resistant molds. It has low viscosity allowing fast wetting of reinforcements, and exhibits excellent adhesion properties to all types of fibers.

It is very handy for most demanding applications, with a very long working time (~ 8 hours at 20° C). It can also be used to step up production to higher temperature resistance, as it can be demolded after a relatively low temperature postcuring. Heat treating to resist higher temperatures may very well come as a second step or at a later time. For this reason this system is very useful when we have to work with plugs or molds that do not resist high temperatures. The initial minimum curing before demolding is 12 hrs at 40° C or 6 hrs at 60° C.

PROPERTIES

Physical properties of SR1710 epoxy resin:

Aspect / colour: Yellowish liquid

Viscosity (m.Pas) at 20 oC / 68 oF: 1450 +- 150

Density at 20 oC / 68 oF: 1.15 (+-0.010)

Physical properties of SD7820 hardener:

Aspect / colour: Clear liquid

Viscosity (m.Pas) at 20 oC / 68 oF: 60 +- 4

Density (g/cm3): 0.957

Mix properties of SR1710 / SD7820 system:

Weight ratio: 100 / 36 g

Volume ratio: 100 / 43 ml

Mix viscosity (m.Pas) at 20 oC / 68 oF: 550

Reactivity of SR1710 / SD7820 system:

Pot life on 500 g mix at 20 oC: 5 h 52'

Exothermic peak on 500 g mix (oC) at 20 oC: 155

Time to reach exothermic peak at 20 oC / 68 oF: 6 h 55'

Intrastat Number for this product: Epoxy: 39073000, Hardener: 29213091..

From 24.13€ ...to 37.40€

High temperature epoxy system SR1720 / SD7840

Each kilo includes 0.79 kg resin + 0.21 kg hardener

Epoxy system specially formulated for high temperature resistance. It exhibits low viscosity which makes it suitable for infusion and RTM applications. It also develops good mechanical properties after an initial posturing at low temperature, for example 50 °C, allowing parts to be demolded. This makes the system possible to be used with non heat resistant moulds and prototypes. Higher temperature resistance, up to 200 °C is possible to be achieved later, with subsequent postcuring cycles.

PROPERTIES

Physical properties of SR1720 epoxy resin:

Aspect / colour: Yellowish liquid

Viscosity (cps) at 20 oC / 68 oF: 8500(+-1500)

Density at 20 oC / 68 oF: 1.18(+-0.01)

Physical properties of SD7840 hardener:

Aspect / colour: Reddish yellow liquid

Viscosity (cps) at 20 oC: 22(+-4)

Density (g/cm3): 0.97(+-0.01)

Mix properties of SR1720 / SD7840 system:

Weight ratio: 100 / 26 g

Volume ratio: 100 / 32 ml

Mix viscosity (cps) at 30 oC / 86 oF: 450(+-100)

Reactivity of SR1720 / SD7840 system:

Pot life on 500 g mix at 40 oC: 42'

Exothermic peak on 500 g mix (oC) at 40 oC: > 250 oC

Time to reach exothermic peak at 40 oC: 1h 8'

Intrastat Number for this product: Epoxy: 39073000, Hardener: 29213091..

From 48.08€ ...to 74.53€

Cost / performance epoxy system R482 / H17

Each kilo includes 0.85 kg resin + 0.15 kg hardener

Suitable for marine and wood composites. It has an excellent adhesion to many types of material like old polyester, wood, epoxy, metal and other, and is crystallization free.

Applications:

Production wooden sructures and marine enviroment. Laminating, bonding and protection of wood. Suitable also for laminating with carbon, aramid, glass, and other reinforcements. Hand lay-up, vacuum bagging, compression and all open or closed mold fabricating in general.

Positive features:

Excellent cost / performance ratio, excellent impregnating, low air voids, excellent elongation at break. Very good chemical resistance in the cured state. Very useful system when laminating and repairing very large, outdoor structures where post curing is not possible.

PROPERTIES

Mix ratio by weight: 18 / 100

Pot life of 150 g at 25 oC: 20 min.

Peak exotherm of 150 g at 25 oC: At 16 minutes 198 oC

Demoulding time at 25 oC: 18 hours

For safety - storage instructions please contact.

Intrastat Number for this product: Epoxy: 39073000, Hardener: 29213091..

From 12.59€ ...to 19.71€

Cost / performance epoxy system R482 / H50

Each kilo includes 0.67 kg resin + 0.33 kg hardener

Applications:

Production of glass, aramid, carbon, and all fiber reinforced products. Hand lay-up, vacuum bagging, infusion, winding, compression, RTM and all open or closed mould fabricating in general.

Positive features:

Excellent cost / performance ratio, excellent impregnating, low air voids. Very good chemical resistance in the cured state. Very good filler acceptance, very mild odor.

PROPERTIES

Mix ratio by weight: 50 / 100

Pot life of 150 g at 25 oC: 55 min.

Peak exotherm of 150 g at 25 oC: At 50 minutes 140 oC

Demoulding time at 25 oC: 50 hours

For safety - storage instructions please contact.

Intrastat Number for this product: Epoxy: 39073000, Hardener: 29213091..

From 12.59€ ...to 19.71€

Epoxy trowelable system Mixfill 80 for fairing

Each kilo includes 0.57 kg resin + 0.43 kg hardener

Mixfill 80 is a filled coating formulated based on flexibilized epoxy systems and with high mechanical performance at high percentages of elongation to break (8-15%) and a good impact resistance. Coating is filled under vacuum with a complex of very low density fillers (~ 0.6) and low abrasive power in order to ensure greater sustainability of sanding and machining without scrub tools.

Epoxy system Mixfill 80:

- Excellent quality of application without microbubbles

- Ease of application to the rule or the spatula

- Excellent sandability with flat sanding or sander

- Very low clogging of the abrasive

- Great fineness of the film

- No drying shrinkage during drying

- Low exotherm in thick

- Excellent impact resistance

- Ease of dosing by volume (1/1)

PROPERTIES

Physical properties of Mixfill 80 base:

Aspect / colour: Grey paste

Viscosity (m.Pas) at 20 oC / 68 oF: 71900 ± 14400

Density at 20 oC / 68 oF: 0.6500

Physical properties of Mixfill 80 hardener:

Aspect / colour: White paste

Viscosity (m.Pas) at 20 oC / 68 oF: 106000 ± 21200

Density (g/cm3): 0.4800

Mix properties of Mixfill 80 system:

Weight ratio: 100 / 75 g

Volume ratio: 100 / 100 ml

Mix viscosity (m.Pas) at 20 oC / 68 oF: 106000 ± 21200

Reactivity of Mixfill 80 system:

Exothermic temperature on 500 g mix (oC) at 20 oC: 111 oC

Time to reach exothermic peak on 500 g mix at 20 oC: 52'

Pot life of 500 g mix at 20 oC: 34'

Intrastat Number for this product: Epoxy: 39073000, Hardener: 29213091..

From 27.71€ ...to 42.96€

Versatile epoxy system SR1610 / SD2613 for fairing

Each kilo includes 0.68 kg resin + 0.32 kg hardener

SR1610 / SD2613 is a versatile epoxy formulation designed to mix with hollow microspheres and inorganic fillers. It can adhere to epoxy, polyester, vinylester and polyurethane resins. It is used for the manufacturing of putties for sandable coating from medium to fine grain. It exhibits temperature resistance over 100°C.

PROPERTIES

Mix properties of SR1610 / SD2613 system:

Weight ratio: 100 / 47 g

Volume ratio: 100 ml / 50 ml (or 2/1)

Reactivity of SR1610 / SD2613 system:

Pot life of 500 g mix at 20 oC: 60'

Working time of 3 mm thick coat of putty at 20 oC: 2 hrs

Putty in a coat of 3 mm sandable at 20 oC after: 20 hrs

Intrastat Number for this product: Epoxy: 39073000, Hardener: 29213091..

From 21.15€ ...to 32.78€

Epoxy structural adhesive SR7100 / SD7106 for thin bonding with fast hardener

Each kilo includes 0.69 kg resin + 0.31 kg hardener

ISOBOND SR7100 / SD7106 epoxy system has been specially formulated for thin bonding from 0.1 mm to a few mm. It exhibits high fatigue strength and excellent resistance against microcracks propagation. Application on nonporous surface material is possible. The hand mixing for quantities greater than 200 or 300 grams can be complicated and induce significant risks of inhomogeneous mixture in production. A machine of dosing and mixing may then be considered and become essential in order to avoid any difference in quality.

Epoxy system SR7100 / SD7106:

- High performance adhesive

- Adheres to most materials

- Specifically designed for composite structural bonding

- Excellent resistance against microcracks propagation (high GIc)

- Gel texture easy to apply and mix

- Outstanding wettability of surfaces

PROPERTIES

Physical properties of SR7100 epoxy resin:

Aspect / colour: Blue gel

Viscosity (mPa.s) at 20 oC: 21575 ± 4325

Density at 20 oC: 1,1760

Physical properties of SD7106 hardener:

Aspect / colour: Black gel

Viscosity (mPa.s) at 20 oC: 35000 ± 7000

Density (g/cm3) at 20 oC: 1,0687

Mix properties of SR7100 / SD7106 system:

Weight ratio: 100 / 45 g

Volume ratio: 100 / 50 ml

Mix viscosity at 20 oC: 22300

Reactivity of SR7100 / SD7106 system:

Pot life on 500 g mix at 20 oC: 17'

Exothermic peak on 500 g mix (oC) at 20 oC: 185 oC

Time to reach exothermic peak at 20 oC: 23'

Intrastat Number for this product: Epoxy: 39073000, Hardener: 29213091..

From 28.77€ ...to 44.60€

Top clear 3 component epoxy system SR TopClear 1054 / SD TopClear 1533 / ABU

Each kilo includes 0.55 kg resin + 0.36 kg hardener + 0.09 kg diluent

Shiny, translucent, resistant to UV, and high build epoxy system, that can be brushed or sprayed. It can be used with multiple materials, such as wood, composites, fiberglass or carbon fabrics, paper, cardboard, leather, foam, metal, stone, marble, concrete, etc.

Applications:

Finishing for cosmetic parts, glass / hot coat, varnishing, surfacing, laminating of small parts, carbon "look", light binding, non-structural bonding, surf board repairs, fixing fin box, table top, clear gel coat.

PROPERTIES

Physical properties of SR TopClear 1054 Incolore epoxy resin:

Aspect: Liquid

Colour: Clear to light yellow

Viscosity (mPa.s) at 20 oC: 1.600

Density (Kg/l) at 20 oC: 1.07

Physical properties of SD TopClear 1533 hardener:

Aspect: Liquid

Colour: Clear

Viscosity (mPa.s) at 20 oC: 1.000

Density (Kg/l) at 20 oC: 1.15

Mix properties of SR TC 1054 / SD TC 1533:

Weight ratio: 100 / 66 g

Volume ratio: 100 / 62 ml

Mix viscosity (mPa.s) at 20 oC: 2.100

Gel time at 20 oC: 1h 20'

Thinning / solvent properties of thinner ABU:

Sprayable application: dilute from 15% to 30 % straight after mixing the resin and hardener.

Intrastat Number for this product: Epoxy: 39073000, Hardener: 29213091..

From 53.06€ ...to 82.25€

VC006 is a Nylon peel ply release fabric suitable for use with different resin systems and a range of technologies like autoclave, vacuum bagging, infusion and hand lamination.

Nylon 6 peelply

Weight: 60 g / m2

Width: 1.50 meters

Max using temperature: 170 oC (338 oF)

Usage recommendation: To avoid amine, dust or other contamination of the application surface or cured substrate, do not remove cured peel ply before continuing the lamination or paintwork. For easiest peeling properties do not remove before full cure (the harder the resin system, the easier the peeling)

Best storage recommendations: Store in a cool and dry environment. Recommended temperature range of storage is between 10 - 30 °C and relative humidity between 50 - 75%. Keep in the original packaging until use.

Intrastat Number for this product: 54071000..

From 1.85€ ...to 2.77€

VC007 is a Nylon peel ply release fabric suitable for use with different resin systems and a range of technologies like autoclave, vacuum bagging, infusion and hand lamination.

Material: Nylon 66

Weight: 68 g / m2

Available widths: 1.50 meters

Max using temperature: 200 oC

Usage recommendation: To avoid amine, dust or other contamination of the application surface or cured substrate, do not remove cured peel ply before continuing the lamination or paintwork. For easiest peeling properties do not remove before full cure (the harder the resin system, the easier the peeling)

Best storage recommendations: Store in a cool and dry environment. Recommended temperature range of storage is between 10 - 30 °C and relative humidity between 50 - 75%. Keep in the original packaging until use.

Intrastat Number for this product: 54071000..

From 2.48€ ...to 3.40€

VC009 is a Nylon peel ply release fabric suitable for use with different resin systems and a range of technologies like autoclave, vacuum bagging, infusion and hand lamination.

Material: Nylon 66

Weight: 85 g / m2

Available widths: 0.80, 1.00, 1.20 and 1.60 meters (for other widths go to peelply tapes)

Max using temperature: 200 oC

Usage recommendation: To avoid amine, dust or other contamination of the application surface or cured substrate, do not remove cured peel ply before continuing the lamination or paintwork. For easiest peeling properties do not remove before full cure (the harder the resin system, the easier the peeling)

Best storage recommendations: Store in a cool and dry environment. Recommended temperature range of storage is between 10 - 30 °C and relative humidity between 50 - 75%. Keep in the original packaging until use.

Intrastat Number for this product: 54071000..

From 1.65€ ...to 2.57€

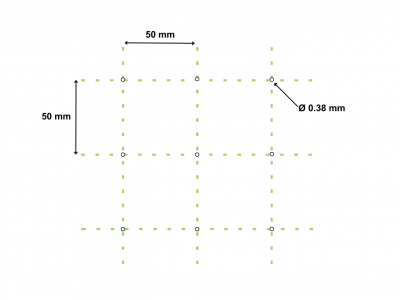

Width: 1.50 meter

Thickness: 30μ

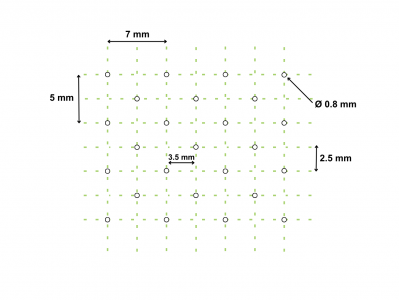

Density of perforation (step): Every 50 mm

Average size of perforation: 0.38 mm

Max temp: 170 oC (338 oF)

Intrastat Number for this product: 54071000..

0.42€

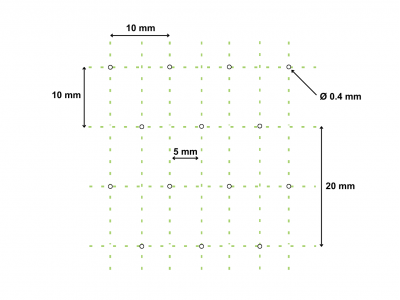

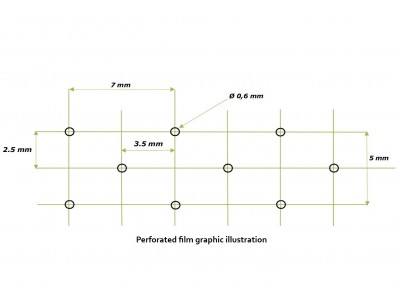

Width: 1.00 and 1.50 meters

Film thickness: 25μ

Density of perforation: Every 14 mm

Average size of perforation: 0.5 mm

Max temp: 120 oC (248 oF)

Intrastat Number for this product: 54071000..

0.35€

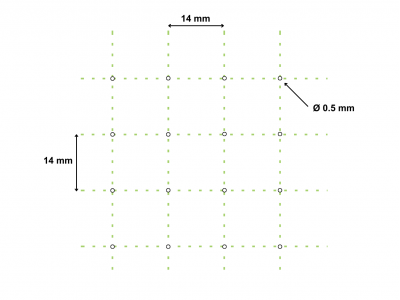

Width: 0.50, 1.00 and 1.50 meters

Film thickness: 45μ

Density of perforation: Every 10 mm

Average size of perforation: 0.4 mm

Max temp: 120 oC (248 oF)

More suitable for use with pre-impregnated

Intrastat Number for this product: 54071000..

0.63€

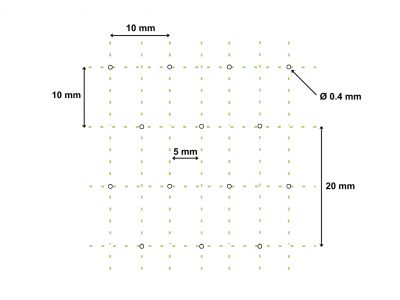

Width: 1.50 meter

Thickness: 30μ

Density of perforation (step): Every 5 mm

Average size of perforation: 0.8 mm

Max temp: 170 oC (338 oF)

Intrastat Number for this product: 54071000..

0.42€

Width: 1.50 meter

Thickness: 30μ

Density of perforation (step): Every 10 mm

Average size of perforation: 0.4 mm

Max temp: 170 oC (338 oF)

More suitable for use with pre-impregnated

Intrastat Number for this product: 54071000..

0.42€

FEP release film HT 260 is ideal for direct laminate contact, offering high durability and conformity. With excellent release properties, it peels off easily after the vacuum bagging processes. Its high elongation and suitability for temperatures up to 260 °C make it versatile for various high-performance applications.

Technical characteristics:

Specific weight: 2.18 g / cm3

Width: 1.20 m

Thickness: 25 micron

Hardness: 55 - 61 shore D

Tensile strength: > 30 N/mm2

Elongation: > 400%

Temperature: -200 / +260 °C (-328 / +500 °F)

Intrastat Number for this product: 54071000..

From 2.53€ ...to 3.38€

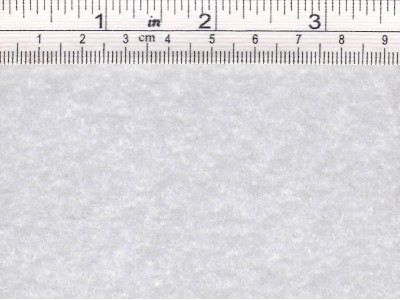

VC014 is a non-woven breather/bleader fabric made with polyester fibrous material, ideally suited for ventilation and absorption of excess matrix. It can be used at ambient and high temperature applications, both for vacuum bagging, autoclave and more applications. Due to its multidirectional high elongation and drapability this breather fabric is able to follow the most complex lamination surfaces.

Technical characteristics:

Material: Polyester non-woven

Weight: 150 g / m2

Thickness: 1.6 mm

Max use temperature: 180 oC

Width: 1.00 and 1.50 meters

DIRECTIONS OF USE

Pre-production trials are recommended to confirm suitability with your unique laminate schedules and processes. It can be used in multiple layers to increase resin absorption capacity. Different areal weights with analogous resin absorption capacity are available upon request.

Intrastat Number for this product: 54071000..

From 0.91€ ...to 1.83€

Self Adhesive PTFE Glass Fabric is a material consisting of a layer of PTFE (polytetrafluoroethylene, commonly known as Teflon) coated glass fabric with an adhesive backing. PTFE is known for its non-stick properties and resistance to high temperatures and chemicals. The adhesive film simplifies the installation, ensuring secure attachment to surfaces without the need for additional adhesives or bonding agents. This combination offers a versatile solution for applications requiring both strength and non-stick properties, making it suitable for a wide range of industrial applications.

Technical characteristics:

Weight (fabric): 270 g/m²

Width: 1.00 m

PTFE content: 60%

Thickness (fabric): 0,13 mm

Adhesive type: Silicone

Adhesive thickness: 0.06 mm

Max. use temperature: up to 260°C

DIRECTIONS OF USE

Prepare the surface by cleaning it thoroughly. Cut the fabric to the desired size, then peel off the backing to expose the adhesive side. Apply the adhesive side of the fabric firmly onto the surface, ensuring proper adhesion.

Intrastat Number for this product: 54071000..

From 20.16€ ...to 23.70€

PTFE Glass fabric is a type of material where glass fabric is coated with a layer of PTFE (polytetrafluoroethylene), commonly known as Teflon. This version features a porous structure. This porous structure allows air or fluids to pass through the fabric while maintaining the properties of PTFE, such as non-stick properties, resistance to high temperatures, and chemical inertness. Porous PTFE coated glass fabric is designed for applications where breathability, the ability to transmit fluids or gases and release properties are required, for vacuum bag lay-up composites and metal-to-metal bonding structures.

Technical characteristics:

Area weight: 80 g/m²

Width: 1.27 m

Thickness: 0.07 mm

Porosity: 20 - 40%

PTFE content: 20%

Max use temperature: up to 260 oC

Intrastat Number for this product: 54071000..

From 6.47€ ...to 10.01€

PTFE Glass fabric is a type of material where glass fabric is coated with a layer of PTFE (polytetrafluoroethylene), commonly known as Teflon. This version features a non-porous structure. This non-porous structure makes it effectively waterproof while maintaining the properties of PTFE, such as non-stick properties, resistance to high temperatures, and chemical inertness. Non-porous PTFE coated glass fabric is designed to better control surface resin on the part, for applications where moisture resistance is required, for vacuum bagging and infusion. It is compatible with epoxy, polyester and vinyl ester resin.

Technical characteristics:

Area weight: 135 g/m²

Width: 1.27 m

Thickness: 0.08 mm

PTFE content: 35%

Max use temperature: up to 260 oC

Intrastat Number for this product: 54071000..

From 6.72€ ...to 10.26€

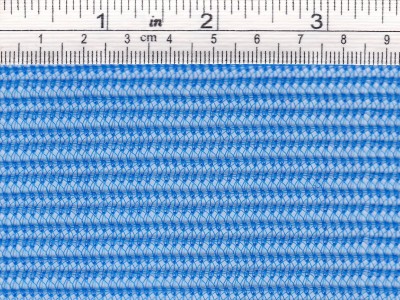

VC016 is a flow fabric used in vacuum-assisted resin infusion processes, commonly employed in composite manufacturing. The purpose of the fabric is to distribute and control the flow of resin throughout the reinforcement material, ensuring a uniform and efficient impregnation of the fibers.

Material: flow fabric blue (soft)

Width: 1.50 m

Weight: 120 g / m2

Thickness: 50 μ

Intrastat Number for this product: 54071000..

From 1.73€ ...to 2.65€

VC017 is a flow fabric used in vacuum-assisted resin infusion processes, commonly employed in composite manufacturing. The purpose of the fabric is to distribute and control the flow of resin throughout the reinforcement material, ensuring a uniform and efficient impregnation of the fibers.

Material: flow fabric green (harder)

Widths: 0.90, 1.50 and 2.00 m

Weight: 135 g / m2

Thickness: 60 μ

Intrastat Number for this product: 56081919..

From 1.63€ ...to 2.55€

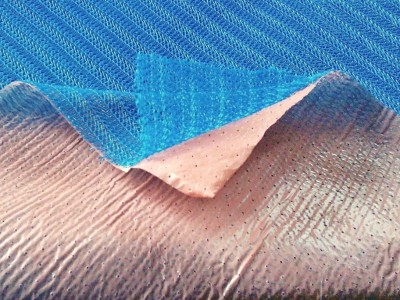

VC0172 is a unique combination that integrates Flow fabric & Perforated film into a single product. Besides a reduction in layup costs, it provides exceptional resin distribution properties and consistent air removal throughout the vacuum-assisted resin infusion process. Its excellent flexibility makes it an ideal choice for intricate mold designs.

Materials: blue flow fabric + pink perforated film

Width: 1.45 m

Weight: 190 g / m2 (± 5%)

Thickness: 60 μ

Max temp: 120 oC (248 oF)

Intrastat Number for this product: 56081919..

From 3.22€ ...to 4.32€

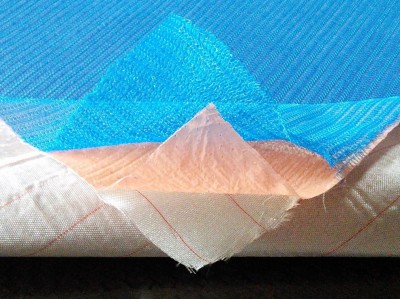

VC0173 is a unique combination that integrates Flow fabric, Perforated film and Peel ply into a single product. Besides reducing handling times and layup costs, it offers exceptional resin distribution properties, with limited losses, and ensures consistent air removal throughout the vacuum-assisted resin infusion process. It exhibits excellent flexibility, making it an ideal choice for intricate mold designs, while its form could minimize or eliminate the need for sanding and abrading works.

Materials: blue flow fabric + pink perforated film + peelply VC009

Width: 1.52 m

Weight: 260 g / m2

Thickness: 80 μ

Max temp: 120 oC (248 oF)

Intrastat Number for this product: 56081919..

From 5.75€ ...to 6.67€

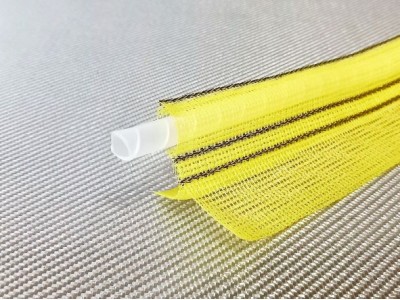

Flow fabric tape “Omega” is designed especially for use with a 12-13 mm spiral tube (not included). It is stitched lengthwise three times, making it very stable and easy to place. It doesn’t leave any print on the applied surface and the tube is easily inserted. Suitable for resin infusion, CRIMP, VARTM, VAP processes and compression moulding.

Technical characteristics:

Material type: Polyethylene

Weaving style: Knitted

Roll length: 50 lm

Width: 75 mm

Mesh (nominal thickness): 1,1 mm

Composition: 100% HDPE Monofilament yarn

Intrastat Number for this product: 56081919..

47.00€

VC019 is a spiral tube used in resin infusion processes to facilitate the flow of resin from the resin feed tube into and around a resin infusion project. This tube is positioned, often underneath the feed line, in order to guide the resin flow into the more intricate or remote corners of the composite part. It ensures that the resin is evenly distributed throughout the entire mold or structure, reaching areas that might be harder to access through the main feed line alone. This contributes to achieving a uniform impregnation and helps prevent issues such as dry spots or uneven resin distribution in the final product.

Outside diameter: 12 mm

Inside diameter: 9 mm

Intrastat Number for this product: 39239000..

21.00€

VC020 is a spiral tube used in resin infusion processes to facilitate the flow of resin from the resin feed tube into and around a resin infusion project. This tube is positioned, often underneath the feed line, in order to guide the resin flow into the more intricate or remote corners of the composite part. It ensures that the resin is evenly distributed throughout the entire mold or structure, reaching areas that might be harder to access through the main feed line alone. This contributes to achieving a uniform impregnation and helps prevent issues such as dry spots or uneven resin distribution in the final product.

Outside diameter: 12 mm

Inside diameter: 9 mm

Intrastat Number for this product: 39239000..

50.00€

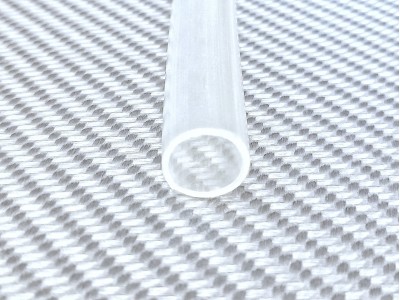

Low density polyethylene pipe for all kinds of thermosetting resins. Suitable for resin distribution in infusion and vacuum bagging processes.

Material type: Polyethylene

External diameter: 8 mm

Internal diameter: 6 mm

Pipe thickness: 1 mm

Max temp: 90 oC

Intrastat Number for this product: 39173900..

0.40€

Low density polyethylene pipe for all kinds of thermosetting resins. Suitable for resin distribution in infusion and vacuum bagging processes.

Material type: Polyethylene

External diameter: 10 mm

Internal diameter: 8 mm

Pipe thickness: 1 mm

Max temp: 90 oC

Intrastat Number for this product: 39173900..

0.52€

Low density polyethylene pipe for all kinds of thermosetting resins. Suitable for resin distribution in infusion and vacuum bagging processes.

Material type: Polyethylene

External diameter: 12 mm

Internal diameter: 10 mm

Pipe thickness: 1 mm

Max temp: 90 oC

Intrastat Number for this product: 39173900..

0.60€

Low density polyethylene pipe for all kinds of thermosetting resins. Suitable for resin distribution in infusion and vacuum bagging processes.

Material type: Polyethylene

External diameter: 15 mm

Internal diameter: 12 mm

Pipe thickness: 1 mm

Max temp: 90 oC

Intrastat Number for this product: 39173900..

0.90€

Connection net is used in infusion, in order to modify the flow.

Intrastat Number for this product: 39239000..

0.55€

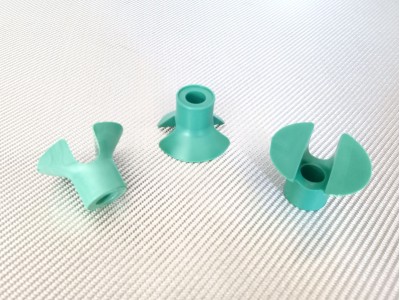

Disposable plastic infusion plug with rounded edges to protect vacuum bags from tearing. Suitable for tubes with 12 mm external diameter (usually 10 mm inner diameter).

Material type: Polypropylene

Maximum use temperature: 120°C (248°F)

Intrastat Number for this product: 39239000..

1.10€

Disposable plastic infusion plug with rounded edges to protect vacuum bags from tearing. Suitable for tubes with 15 mm external diameter (usually 12,5 mm inner diameter).

Material type: Polypropylene

Maximum use temperature: 120°C (248°F)

Intrastat Number for this product: 39239000..

1.10€

Disposable plastic infusion plug with rounded edges to protect vacuum bags from tearing. Suitable for tubes with 16 mm external diameter (usually 13 mm inner diameter).

Material type: Polypropylene

Maximum use temperature: 120°C (248°F)

Intrastat Number for this product: 39239000..

1.10€

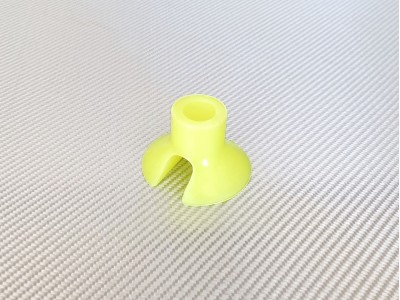

Disposable plastic infusion plug with rounded edges to protect vacuum bags from tearing. Suitable for tubes with 17 mm external diameter (usually 14 mm inner diameter).

Material type: Polypropylene

Maximum use temperature: 120°C (248°F)

Intrastat Number for this product: 39239000..

1.10€

Roll length: 150 lm

Roll price: 66.52 EUR / 150 lm roll

Price / lm: 0.44 EUR

Width: 2.54 cm

Thickness: 50 μm

Max temp: 205 oC (401 oF)

Breaking elongation: 400%

Intrastat Number for this product: 39209959..

66.52€

Roll length: 200 lm

Roll price: 93.14 EUR / 200 lm roll

Price / lm: 0.62 EUR

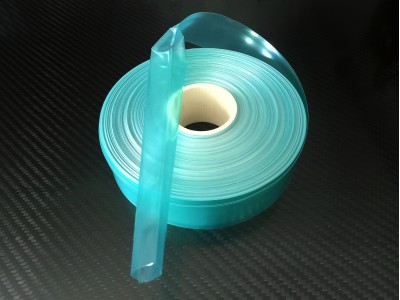

Self-releasing tubular vacuum film, also suitable for the manufacturing of hollow composite structures by blow moulding. The main benefits of this film are high elongation and easy removal after cure, designed to avoid damage to components.

Width: 5.08 cm

Thickness: 100 μm

Max temp: 205 oC (401 oF)

Breaking elongation: 400%

Intrastat Number for this product: 39209959..

93.14€

Roll length: 200 lm

Roll price: 110.00 EUR / 200 lm roll

Price / lm: 0.55 EUR

Self-releasing tubular vacuum film, also suitable for the manufacturing of hollow composite structures by blow moulding. The main benefits of this film are high elongation and easy removal after cure, designed to avoid damage to components.

Width: 6.00 cm

Thickness: 100 μm

Max temp: 205 oC

Breaking elongation: 400%

Intrastat Number for this product: 39209959..

110.00€

Roll length: 200 lm

Roll price: 129.18 EUR / 200 lm roll

Price / lm: 0.52 EUR

Self-releasing tubular vacuum film, also suitable for the manufacturing of hollow composite structures by blow moulding. The main benefits of this film are high elongation and easy removal after cure, designed to avoid damage to components.

Width: 7.50 cm

Thickness: 100 μm

Max temp: 205 oC (401 oF)

Breaking elongation: 320%

Intrastat Number for this product: 39209959..

129.18€

Roll length: 200 lm

Roll price: 117.78 EUR / 200 lm roll

Price / lm: 0.59 EUR

Width: 10.16 cm

Thickness: 50 μm

Max temp: 205 oC (401 oF)

Breaking elongation: 320%

Intrastat Number for this product: 39209959..

117.78€

0.42 EUR / linear meter

Thickness: 140 μm

Width: 12 cm

Max temp: 70 oC (158 oF)

Intrastat Number for this product: 39209959..

0.42€

0.48 EUR / linear meter

Thickness: 140 μm

Width: 15 cm

Max temp: 70 oC (158 oF)

Intrastat Number for this product: 39209959..

0.48€

0.60 EUR / linear meter

Thickness: 140 μm

Width: 23 cm

Max temp: 70 oC (158 oF)

Intrastat Number for this product: 39209959..

0.60€

0.88 EUR / linear meter

Thickness: 140 μm

Width: 35 cm

Max temp: 70 oC / 158 oF

Intrastat Number for this product: 39209959..

0.88€

Width: 45.72 cm

Thickness: 50 μm

Max temp: 170 oC (338 oF)

Breaking elongation: 360%

Intrastat Number for this product: 39209959..

From 0.63€ ...to 1.55€

Width: 100 cm

Thickness: 70 μm

Max temp: 140 oC / 284 oF

Tensile strength: >35 Mpa

Breaking elongation: 650%

Intrastat Number for this product: 39209959..

From 1.24€ ...to 2.16€

Width: 120 cm

Thickness: 50 μm

Max temp: 170 oC (338 oF)

Tensile strength: >35 Mpa

Breaking elongation: 650%

Intrastat Number for this product: 39209959..

From 1.63€ ...to 2.55€

Width: 150 cm

Thickness: 50 μm

Max temp: 170 oC (338 oF)

Tensile strength: >35 Mpa

Breaking elongation: 650%

Intrastat Number for this product: 39209959..

From 2.03€ ...to 2.95€

Width: 200 cm

Thickness: 70 μm

Max temp: 140 oC (284 oF)

Tensile strength: >35 Mpa

Breaking elongation: 650%

Intrastat Number for this product: 39209959..

From 0.68€ ...to 1.60€

Width: 240 cm

Thickness: 50 μm

Max temp: 170 oC (338 oF)

Tensile strength: >35 Mpa

Breaking elongation: 650%

Intrastat Number for this product: 39209959..

From 0.68€ ...to 1.60€

Modified nylon

Widths: 4 m, 6 m, 8 m and 10 m

Thickness: 75 μm

Max temp: 120 oC (248 oF)

Breaking elongation: 600%

Intrastat Number for this product: 39209959..

From 0.68€ ...to 1.60€

Designed for vacuum bagging operations, mastic sealant tapes are used for both "bag to tool" and "bag to bag" applications. They exhibit strong tack, ensuring an air-tight seal throughout the curing cycle. They facilitate easy removal, leaving a clean, residue-free surface, and require minimum cleanup between the cycles.

Technical characteristics:

Roll length: 21 meters

Max temp: 210 oC (410 oF)

Width: 6 mm (0.6 cm)

Thickness: 2 mm (0.2 cm)

Features & Benefits:

Oven and autoclave compatible

Residue-free tool release

Adheres in low temperatures

Versatile applications

Non-hazardous

Intrastat Number for this product: 40059100

..

From 4.55€ ...to 6.05€

Designed for vacuum bagging operations, mastic sealant tapes are used for both "bag to tool" and "bag to bag" applications. They exhibit strong tack, ensuring an air-tight seal throughout the curing cycle. They facilitate easy removal, leaving a clean, residue-free surface, and require minimum cleanup between the cycles.

Technical characteristics:

Roll length: 15 meters

Max temp: 210 oC (410 oF)

Width: 10 mm (1.0 cm)

Thickness: 3 mm (0.3 cm)

Features & Benefits:

Oven and autoclave compatible

Residue-free tool release

Adheres in low temperatures

Versatile applications

Non-hazardous

Intrastat Number for this product: 40059100..

From 7.00€ ...to 8.55€

Heat shrink tape for manufacturing prepreg wrapped tubes. High shrink and compaction force, release coated both sides. Can withstand temperatures up to 140 - 150 oC. Suitable for in or out of autoclave curing. Also suitable for room temperature, heat gun (self-made prepreg) application. Specialized widths of tapes, different diameters of inner carton core and different grades of shrink films are offered upon request.

Technical characteristics:

Width: 25 mm

Density: 91 g/m3, 27 g/m2

1100 lm: 0.75 kg

Thickness: 30 micron (for reduced step)

Inner diameter of core papertube: 70 mm

Outer diameter of reel: 250 mm

Intrastat Number for this product: 39209959..

21.10€

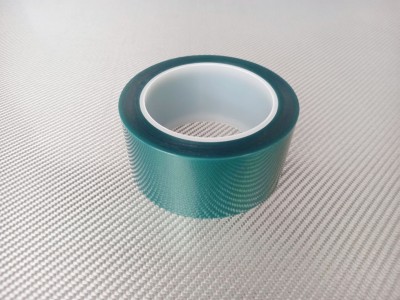

High temperature, pressure sensitive PET (polyester) tape with a silicone adhesive. It can be used to provide an instant, temporary release surface on any material, to hold down vacuum bagging consumables in position, join temporary barriers and also tape flash lines on moulds. It is versatile, easy to remove, tear resistant, has a flat, shiny surface and does not deform in high heat (zero curling and shrinkage). Easily separable from the epoxy, it leaves a clean finish with no residue or damage to the applied surface when removing it.

Technical characteristics:

Material type: PET (polyester)

Roll length: 66 meters

Width: 25 mm

Thickness: 61 μm

Long term working temperature: 120°C (248°F)

Maximum short term working temperature: 228°C (442°F)

Suitable for multiple applications:

Vacuum bagging

Resin infusion

Pre-preg processes

Oven/autoclave curing

Epoxy and polyester surface

Woodworking and resin casting

Various art applications

Intrastat Number for this product: 3919908065..

9.10€

High temperature, pressure sensitive PET (polyester) tape with a silicone adhesive. It can be used to provide an instant, temporary release surface on any material, to hold down vacuum bagging consumables in position, join temporary barriers and also tape flash lines on moulds. It is versatile, easy to remove, tear resistant, has a flat, shiny surface and does not deform in high heat (zero curling and shrinkage). Easily separable from the epoxy, it leaves a clean finish with no residue or damage to the applied surface when removing it.

Technical characteristics:

Material type: PET (polyester)

Roll length: 66 meters

Width: 50 mm

Thickness: 61 μm

Long term working temperature: 120°C (248°F)

Maximum short term working temperature: 228°C (442°F)

Suitable for multiple applications:

Vacuum bagging

Resin infusion

Pre-preg processes

Oven/autoclave curing

Epoxy and polyester surface

Woodworking and resin casting

Various art applications

Intrastat Number for this product: 3919908065..

18.00€

30.12 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 2 mm

Panel size: 950 X 2050 mm

Total surface of 1 panel: 1.95 m2

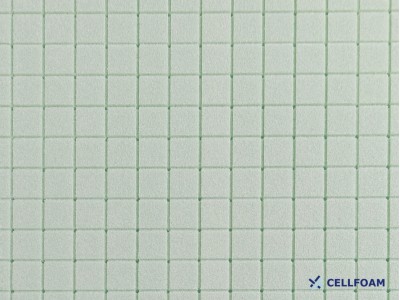

CELLFOAM

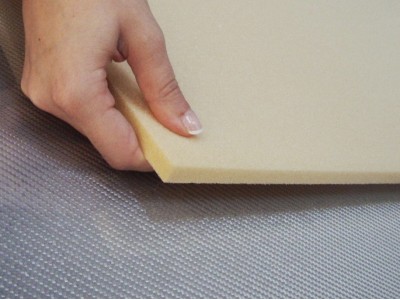

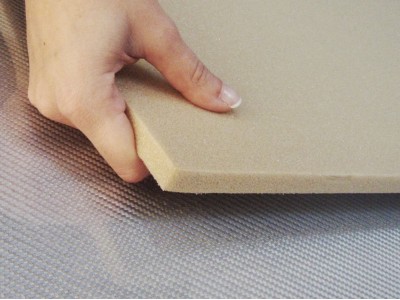

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

30.12€

23.86 EUR / panel

Spec. weight: 60 kg / m3

Thickness: 3 mm

Panel size: 1150 X 2450 mm

Total surface of 1 panel: 2.82 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

23.86€

29.26 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 3 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

29.26€

31.87 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 3 mm

Panel size: 950 X 2050 mm

Total surface of 1 panel: 1.95 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

31.87€

39.13 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 5 mm

Panel size: 950 X 2050 mm

Total surface of 1 panel: 1.95 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

39.13€

39.14 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 7 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

39.14€

44.73 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 8 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

44.73€

47.97 EUR / panel

Spec. weight: 60 kg / m3

Thickness: 10 mm

Panel size: 1150 X 2450 mm

Total surface of 1 panel: 2.82 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

47.97€

55.92 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 10 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

55.92€

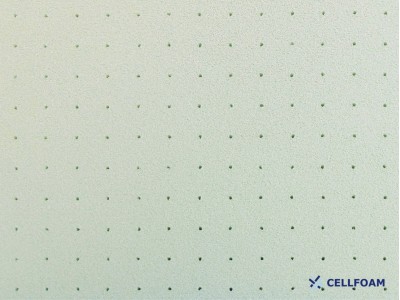

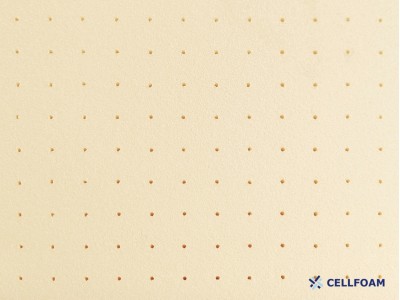

29.43 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 10 mm

Panel size: 1090 X 1020 mm

Total surface of 1 panel: 1.11 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

29.43€

58.15 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 10 mm

Panel size: 950 X 2050 mm

Total surface of 1 panel: 1.95 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

58.15€

54.82 EUR / panel

Spec weight: 60 kg / m3

Thickness: 12 mm

Panel size: 1150 X 2450 mm

Total surface of 1 panel: 2.82 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

54.82€

64.24 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 12 mm

Panel size: 1000 X 2150mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

64.24€

69.78 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 12 mm

Panel size: 950 X 2050 mm

Total surface of 1 panel: 1.95 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

69.78€

66.80 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 13 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

66.80€

67.84 EUR / panel

Spec weight: 60 kg / m3

Thickness: 15 mm

Panel size: 1150 X 2450 mm

Total surface of 1 panel: 2.82 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

67.84€

76.63 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 15 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

76.63€

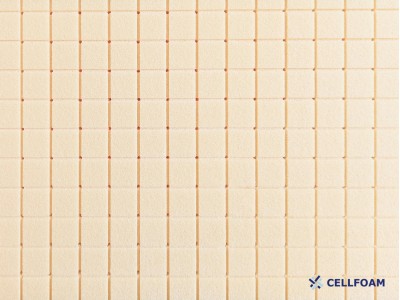

40.35 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 15 mm

Panel size: 1090 X 1020 mm

Total surface of 1 panel: 1.11 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

40.35€

76.33 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 15 mm

Panel size: 950 X 2050 mm

Total surface of 1 panel: 1.95 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

76.33€

61.27 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 15 mm

Panel size: 960 X 1330 mm

Total surface of 1 panel: 1.28 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

61.27€

82.79 EUR / panel

Spec weight: 60 kg / m3

Thickness: 20 mm

Panel size: 1150 X 2450 mm

Total surface of 1 panel: 2.82 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

82.79€

92.30 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 20 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

92.30€

48.59 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 20 mm

Panel size: 1090 X 1020 mm

Total surface of 1 panel: 1.11 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

48.59€

52.35 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 20 mm

Panel size: 1000 X 1070 mm

Total surface of 1 panel: 1.07 m2

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

The HT type is suitable for high temperature applications. For example, it can be used for autoclave prepreg sandwich curing at 120°C and 3 bar pressure. Higher temperature and pressure applications are possible, depending on the tolerance for potential partial collapse (collapse refers to a reduction in thickness without implying a loss of mechanical properties).

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

52.35€

96.78 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 20 mm

Panel size: 950 X 2050 mm

Total surface of 1 panel: 1.95 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

96.78€

149.03 EUR / panel

Spec. weight: 200 kg / m3

Thickness: 20 mm

Panel size: 700 X 1500 mm

Total surface of 1 panel: 1.05 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption