87.59 EUR / panel

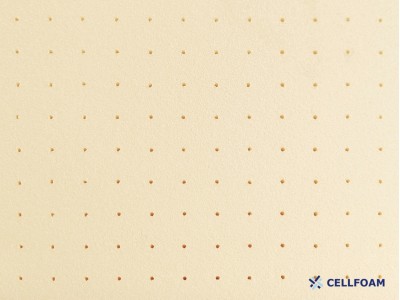

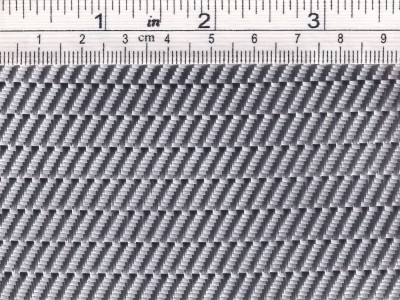

Spec. weight: 80 kg / m3

Thickness: 40 mm

Panel size: 1000 X 1070 mm

Total surface of 1 panel: 1.07 m2

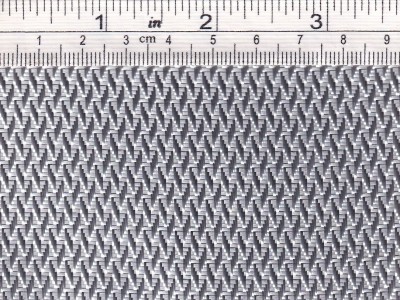

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

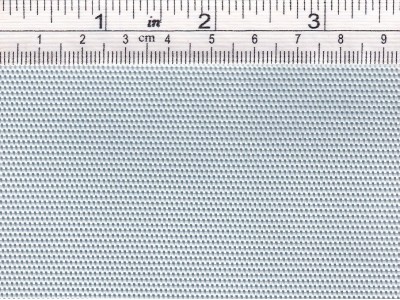

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

The HT type is suitable for high temperature applications. For example, it can be used for autoclave prepreg sandwich curing at 120°C and 3 bar pressure. Higher temperature and pressure applications are possible, depending on the tolerance for potential partial collapse (collapse refers to a reduction in thickness without implying a loss of mechanical properties).

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

87.59€

186.64 EUR / panel

Spec weight: 60 kg / m3

Thickness: 50 mm

Panel size: 1150 X 2450 mm

Total surface of 1 panel: 2.82 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

186.64€

201.86 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 50 mm

Panel size: 1000 X 2150 mm

Total surface of 1 panel: 2.15 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

201.86€

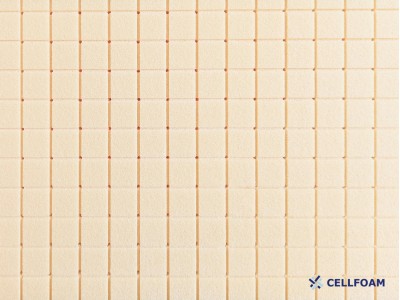

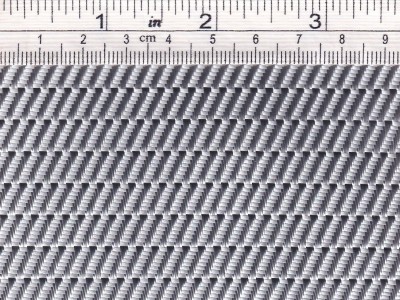

106.87 EUR / panel

Spec. weight: 80 kg / m3

Thickness: 50 mm

Panel size: 1000 X 1070 mm

Total surface of 1 panel: 1.07 m2

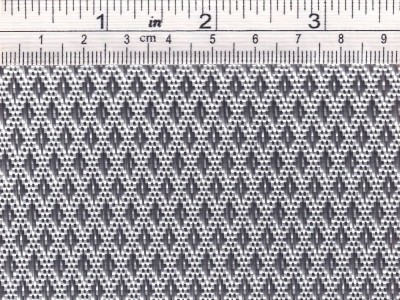

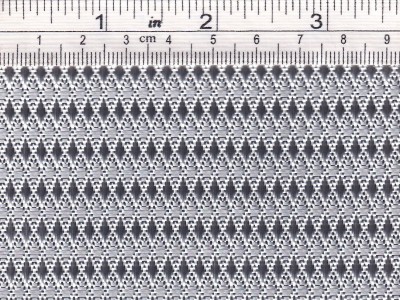

Grooves: 20 mm X 20 mm, on one size, both directions ("one side")

Grooves width: 2 mm

Holes diameter: 2 mm

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. This version is perforated (with holes) and grooved (with carved channels). The perforation and grooves are specifically designed and optimized to facilitate fast resin flow in the infusion/injection process. The perforation allows the resin to pass easily through the foam to the underside, while the grooves distribute the resin flow effectively.

Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper, and can be thermoformed into curves.

The HT type is suitable for high temperature applications. For example, it can be used for autoclave prepreg sandwich curing at 120°C and 3 bar pressure. Higher temperature and pressure applications are possible, depending on the tolerance for potential partial collapse (collapse refers to a reduction in thickness without implying a loss of mechanical properties).

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

106.87€

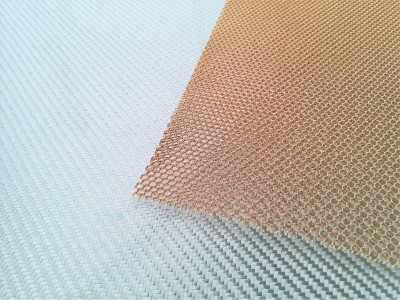

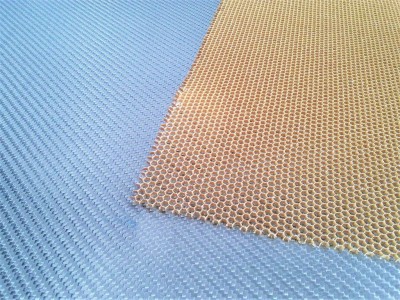

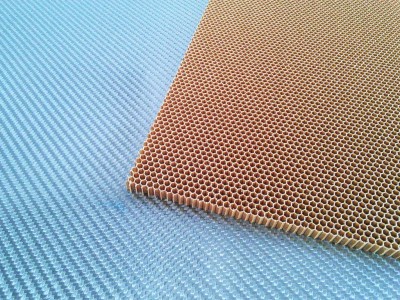

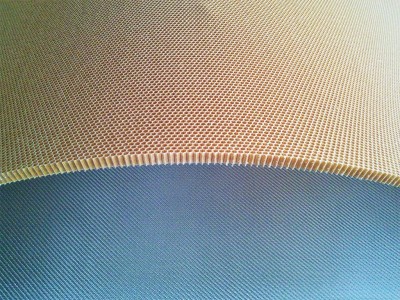

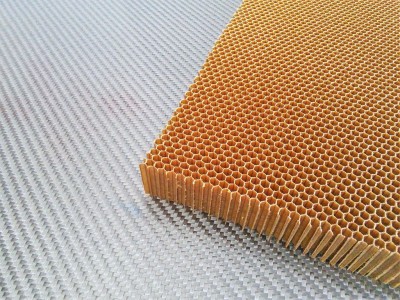

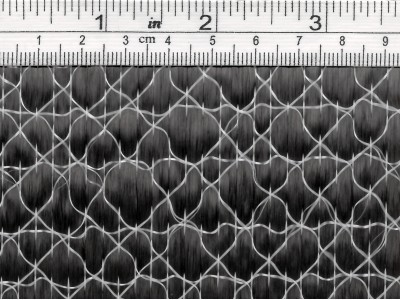

Aramid honeycomb, Nomex or equivalent

79.10 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 1.5 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 300 PSI

Modulus: 18.5 KSI

Plate shear:

Strength (PSI "L" direc): 160

Strength (PSI "W" direc): 90

Modulus (KSI "L" direc): 5.3

Modulus (KSI "W" direc): 3.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

79.10€

123.00 EUR / panel

Spec. weight: 100 kg / m3

Thickness: 50 mm

Panel size: 950 X 1025 mm

Total surface of 1 panel: 0.97 m2

CELLFOAM

Is a lightweight, closed-cell PVC foam designed for universal use in sandwich structures. Ideally suited for both static and dynamic loading, it is compatible with all resin systems. Its excellent stiffness, high strength-to-weight ratio and toughness make it suitable for a wide range of sandwich applications. It can be easily cut with a knife (similar to plasterboards), shaped easily, for example with wood shaping tools, smoothed with sandpaper and can be thermoformed into curves.

MAIN CHARACTERISTICS

High strength and stiffness to weight ratio

Ease of adhesion

Compatible with most types of resin systems

Rot resistant

Good thermal insulation

Self extinguishing, good fire behaviour

Very low water absorption

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thin, usually below 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like to have your panel(s) rolled or cut in other dimensions, please specify.

Intrastat Number for this product: 39211200..

123.00€

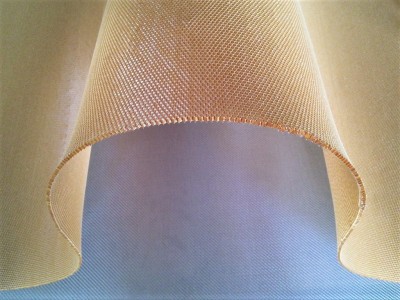

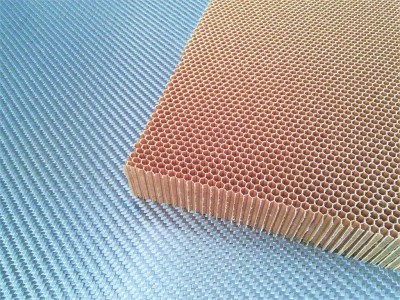

Aramid honeycomb Nomex or equivalent

90.42 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 2 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 300 PSI

Modulus: 18.5 KSI

Plate shear:

Strength (PSI "L" direc): 160

Strength (PSI "W" direc): 90

Modulus (KSI "L" direc): 5.3

Modulus (KSI "W" direc): 3.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

90.42€

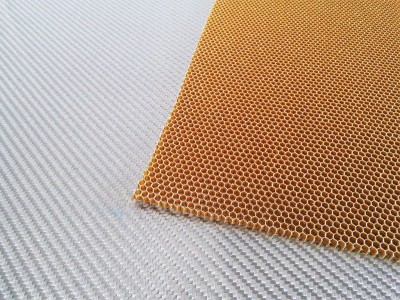

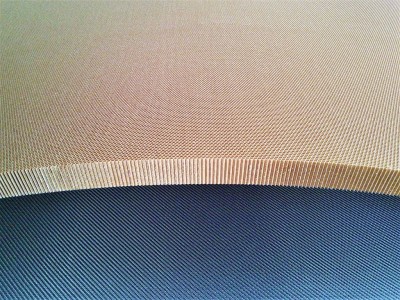

Aramid honeycomb Nomex or equivalent

113.05 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 3 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 300 PSI

Modulus: 18.5 KSI

Plate shear:

Strength (PSI "L" direc): 160

Strength (PSI "W" direc): 90

Modulus (KSI "L" direc): 5.3

Modulus (KSI "W" direc): 3.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

113.05€

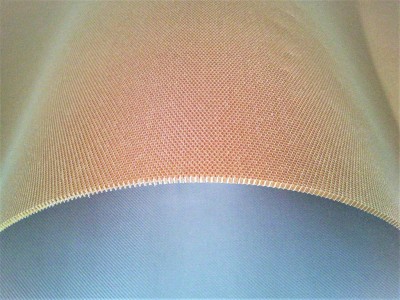

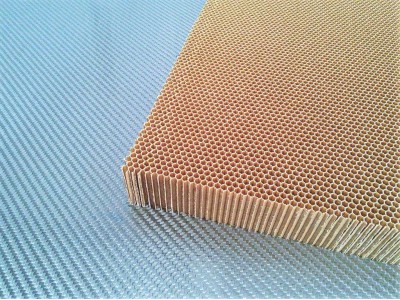

Aramid honeycomb Nomex or equivalent

135.70 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 4 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 300 PSI

Modulus: 18.5 KSI

Plate shear:

Strength (PSI "L" direc): 160

Strength (PSI "W" direc): 90

Modulus (KSI "L" direc): 5.3

Modulus (KSI "W" direc): 3.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

135.70€

Aramid honeycomb, Nomex or equivalent

158.04 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 5 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 300 PSI

Modulus: 18.5 KSI

Plate shear:

Strength (PSI "L" direc): 160

Strength (PSI "W" direc): 90

Modulus (KSI "L" direc): 5.3

Modulus (KSI "W" direc): 3.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

158.04€

Aramid honeycomb, Nomex or equivalent

203.49 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 7 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 150 PSI

Modulus: 11 KSI

Plate shear:

Strength (PSI "L" direc): 100

Strength (PSI "W" direc): 55

Modulus (KSI "L" direc): 4.3

Modulus (KSI "W" direc): 2.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

203.49€

Aramid honeycomb, Nomex or equivalent

268.75 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 10 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 300 PSI

Modulus: 18.5 KSI

Plate shear:

Strength (PSI "L" direc): 160

Strength (PSI "W" direc): 90

Modulus (KSI "L" direc): 5.3

Modulus (KSI "W" direc): 3.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

268.75€

Aramid honeycomb, Nomex or equivalent

384.34 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 15 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 150 PSI

Modulus: 11 KSI

Plate shear:

Strength (PSI "L" direc): 100

Strength (PSI "W" direc): 55

Modulus (KSI "L" direc): 4.3

Modulus (KSI "W" direc): 2.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

384.34€

Aramid honeycomb, Nomex or equivalent

497.28 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 20 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 150 PSI

Modulus: 11 KSI

Plate shear:

Strength (PSI "L" direc): 100

Strength (PSI "W" direc): 55

Modulus (KSI "L" direc): 4.3

Modulus (KSI "W" direc): 2.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

497.28€

Aramid honeycomb, Nomex or equivalent

610.35 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 25 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 150 PSI

Modulus: 11 KSI

Plate shear:

Strength (PSI "L" direc): 100

Strength (PSI "W" direc): 55

Modulus (KSI "L" direc): 4.3

Modulus (KSI "W" direc): 2.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

610.35€

Aramid honeycomb, Nomex or equivalent

723.32 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 30 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 150 PSI

Modulus: 11 KSI

Plate shear:

Strength (PSI "L" direc): 100

Strength (PSI "W" direc): 55

Modulus (KSI "L" direc): 4.3

Modulus (KSI "W" direc): 2.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

723.32€

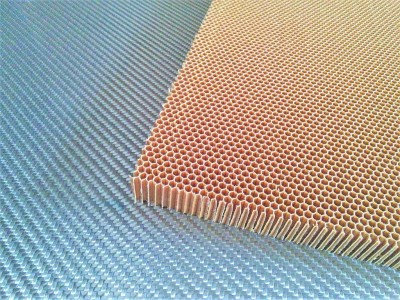

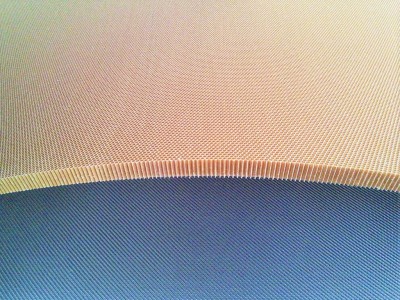

Aramid honeycomb, Nomex or equivalent

964.43 EUR / panel

Panel minimum size: 1.25 X 2.50 m

Total surface of 1 panel: 3.125 sqm

Thickness: 40 mm

Density: 48 kg / m3

Cell size: 3.2 mm (hexagonal)

MECHANICAL PROPERTIES

Compression:

Strength: 150 PSI

Modulus: 11 KSI

Plate shear:

Strength (PSI "L" direc): 100

Strength (PSI "W" direc): 55

Modulus (KSI "L" direc): 4.3

Modulus (KSI "W" direc): 2.1

Ultra lightweight, aramid honeycomb used in sandwich constructions. Unlike metals, Nomex provides galvanic corrosion resistance (also against corrosion of metal inserts) and allows the use of carbon skins. Other definite advantages are low thermal expansion and conductivity and high heat and fire resistance. Its superior mechanical properties and high dimensional stability under heat and moisture make it suitable for a large variety of high-end applications.

In order for very few individual panel(s) to be shipped, we usually roll them up (if they are thinner than 5 mm) or cut them, so they fit in our 37 X 38 X 114 cm carton box. If you like your panel(s) rolled or cut in other dimensions, please specify.

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses. Data sheets and certificates of conformity are promptly provided upon request.

Intrastat Number for this product: 4823909000..

964.43€

40.00 EUR / 10 m2

4.00 EUR / m2 (Minimum order quantity 10 m2)

Thickness: 10 mm

Cell size: 8 mm

Density: 58 kg / m3

kg/m2: 0.58

m2/kg: 1.73

Unexpanded, unimpregnated plain paper honeycomb. A cost efficient alternative to nomex and PVC foam, it can be used in many less demanding applications, where core weight is not a very important factor. It can be expanded and used dry, or impregnated (with any resin system) to gain additional strength and moisture resistance. Typical applications include mold construction (where it is used to lower weight, gain thickness and stability, and to avoid distortion,) light weight furniture, automotive, and boat construction (above waterline or interior).

Intrastat Number for this product: 48239085..

40.00€

42.65 EUR / 5 m2

8.53 EUR / m2(Minimum order quantity 5 m2)

Thickness: 30 mm

Cell size: 8 mm

Density: 58 kg / m3

kg/m2: 1.74

m2/kg: 0.57

Unexpanded, unimpregnated plain paper honeycomb. A cost efficient alternative to nomex and PVC foam, it can be used in many less demanding applications, where core weight is not a very important factor. It can be expanded and used dry, or impregnated (with any resin system) to gain additional strength and moisture resistance. Typical applications include mold construction (where it is used to lower weight, gain thickness and stability, and to avoid distortion,) light weight furniture, automotive, and boat construction (above waterline or interior).

Intrastat Number for this product: 48239085..

42.65€

1.00 kg set (0.76 kg resin + 0.24 kg hardener)

A system of 2 liquid components that when mixed, expands into cellular foam. After cure, it becomes very tough, and exhibits high performance, unique characteristics not possible to obtain by other expanding or liquid foams like polyurethane, polystyrene etc.

The PB170 / DM03 cellular foam production system expands and hardens to a final density of 170 kg / m3. The DM03 is the faster hardener.

Product description

The foaming products are 2 component systems (resin + hardener) developed for "in situ" low density foam production. They can be used to fill mold cavities, and avoid the use of low density fillers and/or the cost of machining of other readily expanded foams like PVC. They come white, but can be colored by adding any epoxy compatible pigment. The final density of the foam is a result of the choice of the resin. The PB170 resin provides approximately 170 kg/m3 foam. The hardener (in this case the DM03) influences only the curing time and not the potential thickness or final density of each shot (or layer) in the cast part.

The process can be separated in 2 steps:

step 1: The mixed resin+hardener expand rapidly into foam

step 2: The foam hardens slowly

Key features:

"In situ" and "in mold" manufacturing of low density foam core helps to avoid the use of low density fillers or CNC machining of expanded foams. Good adhesion onto all type of materials like prepregs and wet/dry epoxy, polyester and vinylester systems. Homogeneous density, floating volume, and very low water absorption. Can be used to increase the density of other cores and honeycomb. Foam blocks can be machined to produce models and prototypes.

Physical properties of resin PB170:

Color: White

Viscosity at 25 oC / 77 oF: 8000 (+-1500)

Density: 1.12 (+-0.01)

Physical properties of hardener DM03:

Color: Light yellow

Viscosity at 20 oC / 68 oF: 210 (+-40)

Density at 20 oC / 68 oF: 1.00 (+-0.01)

Mixing ratio: 31 hardener to 100 p.b.w. resin

Properties of cured system:

Final density after free expansion at 20 oC / 68 oF: 170 (+-20) kg / m3

Expansion ratio at 20 oC / 68 oF: X 6.2

Thermal stability after 24 hrs at room temperature + 6 hrs at 40 oC / 104 oF: Tg1 above 50 oC / 122 oF

Thermal stability after 24 hrs at room temperature + 12 hrs at 60 oC / 140 oF: Tg1 above 70 oC / 158 oF

Exothermic parameters: Are the thermal conductivity of substrate, open or closed mold, geometry and thickness, temperature of materials and mold, ambient temperature, volume and mass of the casting. When casting onto a thick laminate that is curing, the heat produced by the resin system can increase the reactivity of the foaming system.

Intrastat Number for this product: Epoxy: 39073000, Hardener: 38249098..

From 28.22€ ...to 38.56€

1.00 kg set (0.74 kg resin + 0.26 kg hardener)

A system of 2 liquid components that when mixed, expands into cellular foam. After cure, it becomes very tough, and exhibits high performance, unique characteristics not possible to obtain by other expanding or liquid foams like polyurethane, polystyrene etc.

The PB170 / DM02 cellular foam production system expands and hardens to a final density of 170 kg / m3. The DM02 is the slower hardener.

Product description

The foaming products are 2 component systems (resin + hardener) developed for "in situ" low density foam production. They can be used to fill mold cavities, and avoid the use of low density fillers and/or the cost of machining of other readily expanded foams like PVC. They come white, but can be colored by adding any epoxy compatible pigment. The final density of the foam is a result of the choice of the resin. The PB170 resin provides approximately 170 kg/m3 foam. The hardener (in this case the DM02) influences only the curing time and not the potential thickness or final density of each shot (or layer) in the cast part.

The process can be separated in 2 steps:

step 1: The mixed resin+hardener expand rapidly into foam

step 2: The foam hardens slowly

Key features:

"In situ" and "in mold" manufacturing of low density foam core helps to avoid the use of low density fillers or CNC machining of expanded foams. Good adhesion onto all type of materials like prepregs and wet/dry epoxy, polyester and vinylester systems. Homogeneous density, floating volume, and very low water absorption. Can be used to increase the density of other cores and honeycomb. Foam blocks can be machined to produce models and prototypes.

Physical properties of resin PB170:

Color: White

Viscosity at 25 oC / 77 oF: 8000 (+-1500)

Density: 1.12 (+-0.01)

Physical properties of hardener DM02:

Color: Clear to light yellow

Viscosity at 20 oC / 68 oF: 130 (+-25)

Density at 20 oC / 68 oF: 0.98 (+-0.01)

Mixing ratio: 36 hardener to 100 p.b.w. resin

Properties of cured system:

Final density after free expansion at 20 oC / 68 oF: 170 (+-20) kg / m3

Expansion ratio at 20 oC / 68 oF: X 6.2

Thermal stability after 24 hrs at room temperature + 6 hrs at 40 oC / 104 oF: Tg1 above 50 oC / 122 oF

Thermal stability after 24 hrs at room temperature + 12 hrs at 60 oC / 140 oF: Tg1 above 70 oC / 158 oF

Exothermic parameters: Are the thermal conductivity of substrate, open or closed mold, geometry and thickness, temperature of materials and mold, ambient temperature, volume and mass of the casting. When casting onto a thick laminate that is curing, the heat produced by the resin system can increase the reactivity of the foaming system.

Intrastat Number for this product: Epoxy: 39073000, Hardener: 38249098..

From 29.57€ ...to 39.17€

1.00 kg set (0.76 kg resin + 0.24 kg hardener)

A system of 2 liquid components that when mixed, expands into cellular foam. After cure, it becomes very tough, and exhibits high performance, unique characteristics not possible to obtain by other expanding or liquid foams like polyurethane, polystyrene etc.

The PB250 / DM03 cellular foam production system expands and hardens to a final density of 250 kg / m3. The DM03 is the faster hardener.

Product description

The foaming products are 2 component systems (resin + hardener) developed for "in situ" low density foam production. They can be used to fill mold cavities, and avoid the use of low density fillers and/or the cost of machining of other readily expanded foams like PVC. They come white, but can be colored by adding any epoxy compatible pigment. The final density of the foam is a result of the choice of the resin. The PB250 resin provides approximately 250 kg/m3 foam. The hardener (in this case the DM03) influences only the curing time and not the potential thickness or final density of each shot (or layer) in the cast part.

The process can be separated in 2 steps:

step 1: The mixed resin+hardener expand rapidly into foam

step 2: The foam hardens slowly

Key features:

"In situ" and "in mold" manufacturing of low density foam core helps to avoid the use of low density fillers or CNC machining of expanded foams. Good adhesion onto all type of materials like prepregs and wet/dry epoxy, polyester and vinylester systems. Homogeneous density, floating volume, and very low water absorption. Can be used to increase the density of other cores and honeycomb. Foam blocks can be machined to produce models and prototypes.

Physical properties of resin PB250:

Color: White

Viscosity at 25 oC / 77 oF: 12000 (+-2000)

Density: 1.10 (+-0.01)

Physical properties of hardener DM03:

Color: Light yellow

Viscosity at 20 oC / 68 oF: 210 (+-40)

Density at 20 oC / 68 oF: 1.00 (+-0.01)

Mixing ratio: 31 hardener to 100 p.b.w. resin

Properties of cured system:

Final density after free expansion at 20 oC / 68 oF: 250 (+-25) kg / m3

Expansion ratio at 20 oC / 68 oF: X 4

Thermal stability after 24 hrs at room temperature + 6 hrs at 40 oC / 104 oF: Tg1 above 50 oC / 122 oF

Thermal stability after 24 hrs at room temperature + 12 hrs at 60 oC / 140 oF: Tg1 above 70 oC / 158 oF

Exothermic parameters: Are the thermal conductivity of substrate, open or closed mold, geometry and thickness, temperature of materials and mold, ambient temperature, volume and mass of the casting. When casting onto a thick laminate that is curing, the heat produced by the resin system can increase the reactivity of the foaming system.

Intrastat Number for this product: Epoxy: 39073000, Hardener: 38249098..

From 26.37€ ...to 37.12€

1.00 kg set (0.74 kg resin + 0.26 kg hardener)

A system of 2 liquid components that when mixed, expands into cellular foam. After cure, it becomes very tough, and exhibits high performance, unique characteristics not possible to obtain by other expanding or liquid foams like polyurethane, polystyrene etc.

The PB250 / DM02 cellular foam production system expands and hardens to a final density of 250 kg / m3. The DM02 is the slower hardener.

Product description

The foaming products are 2 component systems (resin + hardener) developed for "in situ" low density foam production. They can be used to fill mold cavities, and avoid the use of low density fillers and/or the cost of machining of other readily expanded foams like PVC. They come white, but can be colored by adding any epoxy compatible pigment. The final density of the foam is a result of the choice of the resin. The PB250 resin provides approximately 250 kg/m3 foam. The hardener (in this case the DM02) influences only the curing time and not the potential thickness or final density of each shot (or layer) in the cast part.

The process can be separated in 2 steps:

step 1: The mixed resin+hardener expand rapidly into foam

step 2: The foam hardens slowly

Key features:

"In situ" and "in mold" manufacturing of low density foam core helps to avoid the use of low density fillers or CNC machining of expanded foams. Good adhesion onto all type of materials like prepregs and wet/dry epoxy, polyester and vinylester systems. Homogeneous density, floating volume, and very low water absorption. Can be used to increase the density of other cores and honeycomb. Foam blocks can be machined to produce models and prototypes.

Physical properties of resin PB250:

Color: White

Viscosity at 25 oC / 77 oF: 12000 (+-2000)

Density: 1.10 (+-0.01)

Physical properties of hardener DM02:

Color: Clear to light yellow

Viscosity at 20 oC / 68 oF: 130 (+-25)

Density at 20 oC / 68 oF: 0.98 (+-0.01)

Mixing ratio: 36 hardener to 100 p.b.w. resin

Properties of cured system:

Final density after free expansion at 20 oC / 68 oF: 250 (+-25) kg / m3

Expansion ratio at 20 oC / 68 oF: X 4

Thermal stability after 24 hrs at room temperature + 6 hrs at 40 oC / 104 oF: Tg1 above 50 oC / 122 oF

Thermal stability after 24 hrs at room temperature + 12 hrs at 60 oC / 140 oF: Tg1 above 70 oC / 158 oF

Exothermic parameters: Are the thermal conductivity of substrate, open or closed mold, geometry and thickness, temperature of materials and mold, ambient temperature, volume and mass of the casting. When casting onto a thick laminate that is curing, the heat produced by the resin system can increase the reactivity of the foaming system.

Intrastat Number for this product: Epoxy: 39073000, Hardener: 38249098..

From 27.79€ ...to 37.78€

Width: 1.00 m

Thickness: 5 mm

Density: 140 kg / m3

Cork sheet is a natural, eco-friendly and sustainable core material for composite applications, easily integrated into fast production cycles due to its low density, very good temperature resistance and good drape characteristics (flexibility). Cork is perfectly aligned with green specifications, and suitable for hand layup, vacuum bagging and infusion processes.

MECHANICAL PROPERTIES

Compressive strength (MPa): 0.30

Compressive modulus (MPa): 5.10

Tensile strength (MPa): 0.60

Shear strength (MPa): 0.90

Shear modulus (MPa): 5.9

Thermal conductivity (w/mk): 0.042

Loss Factor (1KHz): 0.022

Maximum Processing Temperature: 180 oC

Vacuum Bag Processing: up to 150 oC

FEATURES & BENEFITS

Closed air filled cell structure

Low water absorption

Rot resistance

Excellent FST (fire, smoke and toxicity) properties

High level of noise and vibration attenuation

Intrastat Number for this product: 45020000..

From 7.05€ ...to 10.08€

SG715 / SD802 epoxy gel coat system

Price: 31.97 EUR / 1.27 kg set (1.0 kg resin + 0.27 kg hardener)

The SG715 / SD802 is a two component epoxy gel coat that is very easy to spread with brush or roller, and hardens practically without shrinking at room temperature. It gives a hard surface with resistance to abrasion and is easy to polish. Its thixotropic but nevertheless supple consistency makes the resin/hardener mixture easy to apply without bubbles with a shorthaired brush in a layer thickness of 1-3 mm. The SG715 / SD802 system does not run down at edges, corners and vertical surfaces. Allow to gel before applying a second coat. To avoid the risk of delamination, lamination must begin with no delay as soon as the gel coat is no longer tacky. If needed, the system can be made thinner by mixing together with other epoxy systems or epoxy solvent.

PROPERTIES

Color: white and black

Thermal stability: Tg1 = 90 oC / 194 oF after 24 hours at ambient temperature + 8 hours at 60 oC / 140 oF

Mixing ratio: 27 hardener to 100 p.b.w. resin

Pot life of 150 g at 20 oC / 68 oF: 17 minutes

Curing time: 6 hours

Application and curing temp: 18-30 oC / 64.4-86 oF, humidity < 80%

Intrastat Number for this product: Epoxy: 39073000, Hardener: 38249098..

31.97€

SG715 / SD7820 epoxy gel coat system

Price: 40.75 EUR / 1.23 kg set (1.00 kg resin + 0.23 kg hardener)

The SG715 / SD7820 is a two component epoxy gel coat that can be applied with a brush, a roller or a spray gun, and hardens at room temperature. It gives a hard surface with resistance to abrasion and good thermal properties after curing (Tg1 max = 120°C (DSC)). Before applying a possible second coat or laminating, allow the gelcoat to gel. It must be tacky (still sticking on the finger) to avoid any risk of delamination. The SG715 / SD7820 is recommended for building prototypes and scale models. If needed, the system can be made thinner by mixing together with an epoxy solvent.

PROPERTIES

Color: white and black

Thermal stability: Tg1 max = 120°C (DSC)

Mixing ratio: 23 hardener to 100 p.b.w. resin

Gel time at 20 oC: 4 h

Recommended post-curing cycles: 12 h at 20°C+ 24 h at 40°C or 12 h at 20°C+ 8 h at 60°C

Humidity: <70%

Intrastat Number for this product: Epoxy: 39073000, Hardener: 38249098..

40.75€

High temperature SG166 GM / SD902 epoxy gel coat system

Price: 32.63 EUR / 1.24 kg set (1.00 kg resin + 0.24 kg hardener)

The SG166 GM / SD902 is a two component, high temperature resistant epoxy gel coat that has a viscosity suitable for brush application. It cures at room temperature and a post-cure is required before release. It exhibits excellent thermal resistance after post-cure, good abrasion resistance and a very good adhesion between gelcoat and laminate. Recommended for manufacturing of mould with a service temperature of 130 °C max.

PROPERTIES

Color: black

Thermal stability: Tg1 max = 148 oC

Mixing ratio: 24 hardener to 100 p.b.w. resin

Pot life of 150 g mix at 20 oC: 56'

Exothermic peak on 150 g mix at 20 oC: 130 oC

Time to reach exothermic peak on 150 g mix at 20 oC: 1 h 30'

Humidity: < 70%

Intrastat Number for this product: Epoxy: 39073000, Hardener: 38249098..

32.63€

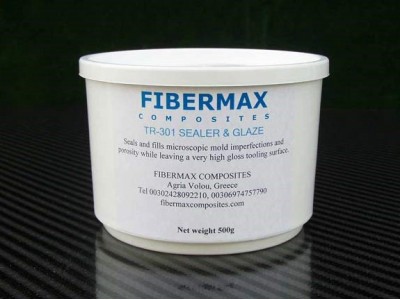

Primer for mold release

DIRECTIONS

Shake well before using. Apply a small amount to the clean surface. Machine buff to thoroughly clean, seal, and finish the surface. On new molds 2 coats are recommended to adequately fill the microscopic pores. Wipe off excess with a clean soft towel and release as required. Keep container sealed when not in use.

Intrastat Number for this product: 34049000..

9.90€

Fire resistant SGi128 / SD228 epoxy gel coat system

Price: 89.21 EUR / 1.68 kg set (0.99 kg resin + 0.69 kg hardener)

The SGi128 / SD228 is a two component, fire resistant epoxy gel coat system, halogen free and flame retardant and has a low smokes opacity and toxicity. This system allows getting the RAILWAY standard EN45545-2: R6 HL1, HL2 and the BUILDING & CONSTRUCTION standard ASTM E84-15b: Class A. It requires post curing in the mould before the part’s release. The lamination can start when the gel is still tacky.

PROPERTIES

Color: white

Thermal stability: Tg1 max = 73 oC

Mixing ratio: 70 hardener to 100 p.b.w. resin

Gel Time at 20 oC: 6 h 40 min

Curing schedule: 24 h at 25 °C or 16 h at 60 °C

Humidity: < 70%

Intrastat Number for this product: Epoxy: 39073000, Hardener: 38249098..

89.21€

SGGCI / SDGCI S epoxy gel coat system

Price: 50.60 EUR / 1.48 kg set (1 kg resin + 0.48 kg hardener)

SG GreenCoat Incolore has a good UV resistance with 51% of biobased carbon in the resin part and 37% in the final mixture.

SGGCI / SDGCI S is a two component epoxy translucent gel coat used in order to protect the laminate and improve shine of finished parts. Apply a thin layer of 0.5-0.8 mm (400-600 g/sqm) with short brush. As soon as the gel coat passes gel time but still tacky, a first layer of epoxy and fabric should be applied in order to achieve best chemical bonding. Do not use spray gun or solvents.

PROPERTIES

Color: translucent

Temp. resistance: 80 oC / 176 oF

Mixing ratio: 100 to 48 p.b.w. (resin to hardener)

Pot life of 100 g at 20 oC / 68 oF: 45 min

Gel time at 20 oC / 68 oF: 2h + 30 min

Curing time: 24 hours

Application and curing temp: 15-30 oC / 59-86 oF

Intrastat Number for this product: Epoxy: 39073000, Hardener: 38249098..

50.60€

Primer for mold release

DIRECTIONS

Shake well before using. Apply a small amount to the clean surface. Machine buff to thoroughly clean, seal, and finish the surface. On new molds 2 coats are recommended to adequately fill the microscopic pores. Wipe off excess with a clean soft towel and release as required. Keep container sealed when not in use.

Intrastat Number for this product: 34049000..

61.44€

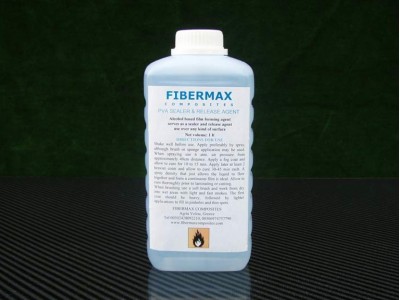

PVA release agent, high temperature

Price: 14.30 EUR / container of 1.0 lt

Polyvinyl alcohol W324 has excellent film forming and release properties. It is used as a release agent in molds and prototypes that are repaired or sanded and do not have a shiny surface. It is resistant to oil, grease and solvents. It is odorless and nontoxic. It has high tensile strength and flexibility. These properties are dependent on humidity, in other words, with higher humidity more water is absorbed. The water, which acts as a plasticiser, will then reduce its tensile strength, but increase its elongation and tear strength. W324 can be use for both room and high temp applications. W324 is fully degradable and is a quick dissolver.

DIRECTIONS

Apply with spray or soft sponge and let dry thoroughly. When using a sponge move with strokes from dry to wet areas. To remove after use or help demolding apply water with pressure. A new, fresh coat must be applied after each and every demolding.

Intrastat Number for this product: 27121090..

14.30€

PVA release agent, high temperature

Polyvinyl alcohol W324 has excellent film forming and release properties. It is used as a release agent in molds and prototypes that are repaired or sanded and do not have a shiny surface. It is resistant to oil, grease and solvents. It is odorless and nontoxic. It has high tensile strength and flexibility. These properties are dependent on humidity, in other words, with higher humidity more water is absorbed. The water, which acts as a plasticiser, will then reduce its tensile strength, but increase its elongation and tear strength. W324 can be use for both room and high temp applications. W324 is fully degradable and is a quick dissolver.

DIRECTIONS

Apply with spray or soft sponge and let dry thoroughly. When using a sponge move with strokes from dry to wet areas. To remove after use or help demolding apply water with pressure. A new, fresh coat must be applied after each and every demolding.

Intrastat Number for this product: 27121090..

126.15€

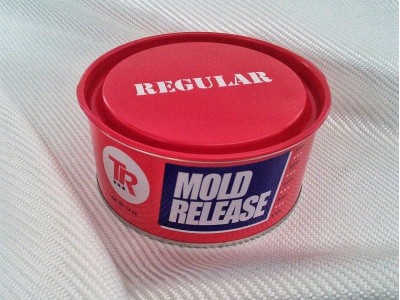

Mold release wax

14.90 EUR / container of 400 g

DIRECTIONS

Apply using a circular, overlapping motion, an even moist film. Allow TR 102 Regular and TR 104 Hi Temp to dry to uniform haze, usually within 5-10 minutes. Hand wipe with a clean dry cloth. For new tooling, it is highly recommended to use the TR 301 Sealer Glaze to improve gloss and seal mold surface. Five to six coats of the paste wax release are normally required for best results. After polish wipe, allow a minimum of 30 minutes between coats for the wax to dry.

Conversion data: 400 g = 14 oz

Intrastat Number for this product: 27121090..

14.90€

Mold release wax, high temperature

16.48 EUR / container of 400 g

DIRECTIONS

Apply using a circular, overlapping motion, even moist film. Allow TR 102 Regular and TR 104 Hi Temp to dry to uniform haze, usually within 5-10 minutes. Hand wipe with a clean dry cloth. For new tooling, it is highly recommended to use the TR 301 Sealer Glaze to improve gloss and seal mold surface. Five to six coats of the paste wax release are normally required for best results. After polish wipe, allow minimum of 30 minutes between coats to allow the wax to set.

Conversion data: 400 g = 14 oz

Intrastat Number for this product: 34049000..

16.48€

Epoxy mould release agent, high temperature

W770 is a versatile, fast evaporating release agent that offers excellent release for various moulding applications. It is odorless, offers high gloss and slip and doesn' t form mold build up. It cures at room temperature and can be applied to mold surfaces at room temperature up to 60 oC.

DIRECTIONS

Apply by spraying, brushing or wiping with a clean lint-free cloth. When spraying, ensure a dry air source is used or use an airless spray system. If possible, before applying W770, warm the mold to approximately 50 oC in order to drive off any moisture entrapped on the mold surface.

Intrastat Number for this product: 27121090..

30.44€

Glossy film forming agent, in liquid form, which serves as a sealer and release agent over any kind of surface.

DIRECTIONS

Shake well before use. Apply preferably by spray, although brush or sponge application may be used. When spraying use a gun with a 1 mm nozzle and use only 1.5-2.0 kg/cm3 air pressure. Apply a fog coat and allow to cure for 10 to 15 min. Apply later a heavier coat and allow to cure. A third coat is required until a continuous film (0.5 - 0.8 mm) is formed. Allow to cure thoroughly prior to laminating or casting. When brushing use a soft brush and work from dry into wet areas with light and fast strokes. The first coat should be heavy, followed by lighter applications to fill in pinholes and thin spots.

TO REMOVE COATING

If film is of the proper thickness it can be blown off with an air nozzle. If not, remove with acetone.

Intrastat Number for this product: 39011090..

21.42€

Glossy film forming agent, in liquid form, which serves as a sealer and release agent over any kind of surface.

DIRECTIONS

Shake well before use. Apply preferably by spray, although brush or sponge application may be used. When spraying use a gun with a 1 mm nozzle and use only 1.5-2.0 kg/cm3 air pressure. Apply a fog coat and allow to cure for 10 to 15 min. Apply later a heavier coat and allow to cure. A third coat is required until a continuous film (0.5 - 0.8 mm) is formed. Allow to cure thoroughly prior to laminating or casting. When brushing use a soft brush and work from dry into wet areas with light and fast strokes. The first coat should be heavy, followed by lighter applications to fill in pinholes and thin spots.

TO REMOVE COATING

If the film is of the proper thickness it can be blown off with an air nozzle. If not, remove with acetone.

Intrastat Number for this product: 39011090..

76.80€

6.00 EUR / container of net volume 1.0 lt

Chemically composed of glass, their hollow form helps reduce matrix density. Their spherical shape prevents stress concentration and, as a consequence, increases cracking resistance of putties. In comparison to microballoons, they are physically harder, more waterproof and somewhat more difficult to sand. They have a fractional survival rate of 80% or more, for continuous use at 250 psi in highly filled resin systems. As a result, glass bubbles are also used as an additive for a number of buoyancy applications, in depths of up to 600 m in seawater. Suggested quantity to add in putties depends upon application.

Particle density: 200g/lt

Bulk density: 125 g/lt

Conversion data: 1 lt = 0.91 qt = 20 fl oz

Intrastat Number for this product: 70182000..

6.00€

11.00 EUR / container of net volume 1.0 lt

Hollow phenolic resin spheres have a distinctive reddish/brown color. This makes them particularly useful for cosmetic joints in wood construction. Although not as waterproof as glass bubbles, microballoons have excellent sanding characteristics. Suggested quantity to add in putties depends upon application. Not compatible with polyester and vinylester resins. Store in tightly closed containers.

Particle density 250g/lt

Bulk density 100g/lt

Conversion data: 1 lt = 0.91 qt = 20 fl oz

Intrastat Number for this product: 39094000..

11.00€

4.50 EUR / container of net volume 1.0 lt

Very fine wood cellulose fibers, used to reinforce the matrix and create structural adhesives for various applications. Microfibers absorb and hold great amounts of resin. Very hard wearing, hard to sand, very good for bonding wood. Where a strong bond is required microfibers should be preferred. Suggested quantity to add in putties depends upon application.

Conversion data: 1 lt = 0.91 qt = 20 fl oz

Intrastat Number for this product: 68062090..

4.50€

4.00 EUR / container of net volume 1.0 lt

Silica is a viscosity regulator, used to control sag characteristics of resin matrix or matrix-filler mixes. Very hard to sand (it is derived from quartz,) is not to be used in large quantities if sanding is anticipated. Very good to create structural adhesives, and useful in applications where a hard wearing surface or scratch resistance is needed (like molds). Suggested quantity to add in putties depends upon application.

Bulk weight: 50 g/lt

Conversion data: 1 lt = 0.91 qt = 20 fl oz

Intrastat Number for this product: 28112200..

4.00€

36.00 EUR / kg

100% pure extra fine copper powder suitable to dilute in epoxy.

Intrastat Number for this product: 70182000..

36.00€

35.08 EUR / container of 10.0 lt

Net weight 0.66 kg

Chemically composed of glass, their hollow form helps reduce matrix density. Their spherical shape prevents stress concentration and, as a consequence, increases cracking resistance of putties. In comparison to microballoons, they are physically harder, more waterproof and somewhat more difficult to sand. They have a fractional survival rate of 80% or more, for continuous use at 250 psi in highly filled resin systems. As a result, glass bubbles are also used as an additive for a number of buoyancy applications, in depths of up to 600 m in seawater. Suggested quantity to add in putties depends upon application.

Particle density 200g/lt

Bulk density 125 g/lt

Conversion data: 1 lt = 0.91 qt = 20 fl oz

Intrastat Number for this product: 70182000..

35.08€

79.68 EUR / 10 lt container

Net weight 1.20 kg

Hollow phenolic resin spheres have a distinctive reddish/brown color. This makes them particularly useful for cosmetic joints in wood construction. Although not as waterproof as glass bubbles, microballoons have excellent sanding characteristics. Suggested quantity to add in putties depends upon application. Not compatible with polyester and vinylester resins. Store in tightly closed containers.

Particle density: 250g/lt

Bulk density: 100g/lt

Conversion data: 1 lt = 0.91 qt = 20 fl oz

Intrastat Number for this product: 39094000..

79.68€

27.45 EUR / container of 10.0 lt

Net weight: 2.50 kg

Very fine wood cellulose fibers, used to reinforce the matrix and create structural adhesives for various applications. Microfibers absorb and hold great amounts of resin. Very hard wearing, hard to sand, very good for bonding wood. Where a strong bond is required microfibers should be preferred. Suggested quantity to add in putties depends upon application.

Conversion data: 1 lt = 0.91 qt = 20 fl oz

Intrastat Number for this product: 68062090..

27.45€

19.96 EUR / 10 lt container

Net weight 0.60 kg

Silica is a viscosity regulator, used to control sag characteristics of resin matrix or matrix-filler mixes. Very hard to sand (it is derived from quartz,) is not to be used in large quantities if sanding is anticipated. Very good to create structural adhesives, and useful in applications where a hard wearing surface or scratch resistance is needed (like molds). Suggested quantity to add in putties depends upon application.

Bulk weight 50 g/lt

Conversion data: 1 lt = 0.91 qt = 20 fl oz

Intrastat Number for this product: 28112200..

19.96€

51.84 EUR / 18 lt container

Net weight 1.20 kg

Chemically composed of glass, their hollow form helps reduce matrix density. Their spherical shape prevents stress concentration and, as a consequence, increases cracking resistance of putties. In comparison to microballoons, they are physically harder, more waterproof and somewhat more difficult to sand. They have a fractional survival rate of 80% or more, for continuous use at 250 psi in highly filled resin systems. As a result, glass bubbles are also used as an additive for a number of buoyancy applications, in depths of up to 600 m in seawater. Suggested quantity to add in putties depends upon application.

Particle density 200g/lt

Bulk density 125 g/lt

Conversion data: 1 lt = 0.91 qt = 20 fl oz

Intrastat Number for this product: 70182000..

51.84€

133.65 EUR / 18 lt container

Net weight 2.10 kg

Hollow phenolic resin spheres have a distinctive reddish/brown color. This makes them particularly useful for cosmetic joints in wood construction. Although not as waterproof as glass bubbles, microballoons have excellent sanding characteristics. Suggested quantity to add in putties depends upon application. Not compatible with polyester and vinylester resins. Store in tightly closed containers.

Particle density 250g/lt

Bulk density 100g/lt

Conversion data: 1 lt = 0.91 qt = 20 fl oz

Intrastat Number for this product: 39094000..

133.65€

40.43 EUR / 18 lt container

Net weight 4.70 kg

Very fine wood cellulose fibers, used to reinforce the matrix and create structural adhesives for various applications. Microfibers absorb and hold great amounts of resin. Very hard wearing, hard to sand, very good for bonding wood. Where a strong bond is required microfibers should be preferred. Suggested quantity to add in putties depends upon application.

Conversion data: 1 lt = 0.91 qt = 20 fl oz

Intrastat Number for this product: 68062090..

40.43€

28.16 EUR / 18 lt container

Net weight 1.08 kg

Silica is a viscosity regulator, used to control sag characteristics of resin matrix or matrix-filler mixes. Very hard to sand (it is derived from quartz,) is not to be used in large quantities if sanding is anticipated. Very good to create structural adhesives, and useful in applications where a hard wearing surface or scratch resistance is needed (like molds). Suggested quantity to add in putties depends upon application.

Bulk weight 50 g/lt

Conversion data: 1 lt = 0.91 qt = 20 fl oz

Intrastat Number for this product: 28112200..

28.16€

Regulates accurately vacuum pressure on the one side of the vacuum line (the side of the curing composite part), while keeping full vacuum pressure on the other (vacuum pump) side. 100% mechanical working principle (not electric), with increased flow rate. Easy to attach/detach SMC pressure gauge (included.) Includes auto-mounting clips for 8X6 mm vacuum line. Metal bracket for panel mounting (included).

Intrastat Number for this product: 90328900..

102.12€

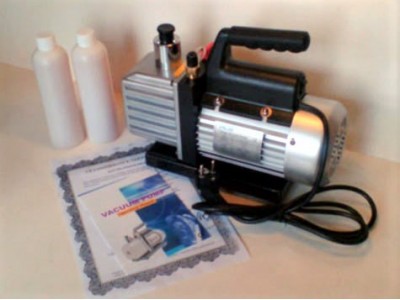

138.22 EUR / piece

Medium vacuum pump, wet (oil-lubricated), double stage, 220V

Technical characteristics:

HP: 1/3

Net weight: 8.6 kg

Air displacement: 2.5 CFM or 70 lt/min

Ultimate vacuum (%): 99.995

Dimensions: 315 X 124 X 240 mm

Lubricating oil included

Limited warranty: 1 year from date of purchase.

Intrastat Number for this product: 84141025..

138.22€

321.38 EUR / piece

Large vacuum pump, wet (oil lubricated), twin stage, 220 V

Technical characteristics:

HP: 1.0

Weight: 16.7 kg

Air displacement: 10 CFM or 283 lt/min

Ultimate vacuum (%): 99.995

Dimensions: 400 X 145 X 270 mm

Lubricating oil included

Limited warranty: 1 year from date of purchase.

Intrastat Number for this product: 84141025..

321.38€

Connects vacuum bag with pump. Can be used for plain vacuum operations or autoclave. (capable to withstand at least 140 oC / 284 oF and 10 bar)

Diameter: 6.4 cm

Intrastat Number for this product: 84149000..

From 11.90€ ...to 13.90€

Cuts through aramid (and all other) fabric patterns with no wrist, hand and finger strain. New, lightweight, handy, ergonomical design that is 100% portable. Works with rechargeable battery or direct 220V AC adapter. The kit includes:

1) Electric scissors

2) 2 pairs of extremely tough carbide steel blades

3) Rechargeable DC battery

4) Charger and power cord

Intrastat Number for this product: 82015000..

98.60€

Carbide steel blades (this product is a spare part for the electric cutting device) will cut through all types of composites fabric.

Intrastat Number for this product: 82015000..

19.00€

AC adapter, charger and power cord (this product is a spare part for the electric cutting device).

Intrastat Number for this product: 82015000..

14.92€

Ultrasonic leak detector, designed and manufactured to detect small leaks in vacuum infusion. Very efficient and easy to use. It includes:

1) Leak Detector

2) Patented Resonator Touch Probe

3) Wave Guide

4) Hi-Fi Folding Headset with volume control

5) Small Carrying Case

6) 9 Volt Battery

Features and benefits:

Not affected by wind

Ten Element LED Bar Graph shows signal strength

On the fly Sensitivity Adjustment aids in locating leaks quickly

True sound reproduction ensures fast recognition of leaks

Not affected from other sounds

Specifications

Mechanical:

Dimensions:(LWD) 4.15"(10.5cm) x 2.4"(61mm) x 0.875"(22.22mm)

Overall length: 5.5"(14cm)

Body materials: ABS

Body finish: blue ABS

Connector: 3.5mm Stereo

Top label: velvet lexan, back printed

Weight: 0.3lb (138gr) includes battery

Electrical:

Airborne sensor sensitivity: -80db/V-μbar

Detection performance: 1.5oz/yr refrigerant

Ultrasound converter type: heterodyne

Frequency response, airborne: 36 kHz to 42 kHz

Heterodyne oscillator: analog

Heterodyne filter: 4 kHz

Sensitivity control: continually variable slide

Output, audio: 0 Hz to 4kHz

Output, visual: 10 element bar graph

Battery type: 9 volt

Run time: 80-120 hrs

Intrastat Number for this product: 85184000..

420.00€

FIBERMAX heat blankets are used to safely and efficiently heat up components to a specific temperature. They are particularly suitable for heating composite laminates such as prepreg, vacuum/infusion lamination and wet layup of carbon and epoxy, ensuring an even temperature distribution across the surface of the material. Heating blankets are utilized, among others, for heating and curing in repair/construction in the aerospace, shipbuilding and the wind turbine manufacturing industry.

Technical characteristics:

Dimensions: 1000 X 500 mm

Heating temperature: adjustable, 0-90°C

Power: 270 W

Voltage: 230 V

Features & Benefits:

- Attached temperature digital controller ranging from 0-90°C (32 - 194°F)

- 3 meter power cord (no plug included)

- 7 mm polyester insulation for minimal heat loss

- Various blankets can be put together with velcro (included at the edge of the blanket) to cover a larger surface

- Straps for fixed installation possible

- Standard sizes available from stock

- Special sizes could be produced upon request

Intrastat Number for this product: 63011000..

616.00€

FIBERMAX heat blankets are used to safely and efficiently heat up components to a specific temperature. They are particularly suitable for heating composite laminates such as prepreg, vacuum/infusion lamination and wet layup of carbon and epoxy, ensuring an even temperature distribution across the surface of the material. Heating blankets are utilized, among others, for heating and curing in repair/construction in the aerospace, shipbuilding and the wind turbine manufacturing industry.

Technical characteristics:

Dimensions: 1000 X 1000 mm

Heating temperature: adjustable, 0-90°C

Power: 450 W

Voltage: 230 V

Features & Benefits:

- Attached temperature digital controller ranging from 0-90°C (32 - 194°F)

- 3 meter power cord (no plug included)

- 7 mm polyester insulation for minimal heat loss

- Various blankets can be put together with velcro (included at the edge of the blanket) to cover a larger surface

- Straps for fixed installation possible

- Standard sizes available from stock

- Special sizes could be produced upon request

Intrastat Number for this product: 63011000..

678.00€

FIBERMAX heat blankets are used to safely and efficiently heat up components to a specific temperature. They are particularly suitable for heating composite laminates such as prepreg, vacuum/infusion lamination and wet layup of carbon and epoxy, ensuring an even temperature distribution across the surface of the material. Heating blankets are utilized, among others, for heating and curing in repair/construction in the aerospace, shipbuilding and the wind turbine manufacturing industry.

Technical characteristics:

Dimensions: 1200 X 800 mm

Heating temperature: adjustable, 0-90°C

Power: 450 W

Voltage: 230 V

Features & Benefits:

- Attached temperature digital controller ranging from 0-90°C (32 - 194°F)

- 3 meter power cord (no plug included)

- 7 mm polyester insulation for minimal heat loss

- Various blankets can be put together with velcro (included at the edge of the blanket) to cover a larger surface

- Straps for fixed installation possible

- Standard sizes available from stock

- Special sizes produced upon request

Intrastat Number for this product: 63011000..

678.00€

FIBERMAX heat blankets are used to safely and efficiently heat up components to a specific temperature. They are particularly suitable for heating composite laminates such as prepreg, vacuum/infusion lamination and wet layup of carbon and epoxy, ensuring an even temperature distribution across the surface of the material. Heating blankets are utilized, among others, for heating and curing in repair/construction in the aerospace, shipbuilding and the wind turbine manufacturing industry.

Technical characteristics:

Dimensions: 1300 X 1300 mm

Heating temperature: adjustable, 0-90°C

Power: 450 W

Voltage: 230 V

Features & Benefits:

- Attached temperature digital controller ranging from 0-90°C (32 - 194°F)

- 3 meter power cord (no plug included)

- 7 mm polyester insulation for minimal heat loss

- Various blankets can be put together with velcro (included at the edge of the blanket) to cover a larger surface

- Straps for fixed installation possible

- Standard sizes available from stock

- Special sizes could be produced upon request

Intrastat Number for this product: 63011000..

730.00€

236.00 EUR / kit

This set of products is everything needed to perform vacuum bagging operations. It includes:

1) 1 vacuum pump (medium size)

2) 1 air filter

3) 6 m rigid pvc pipe

4) 1 distributor

5) 1 negative manometer

6) 1 control valve

7) 3 air-taps

8) 3 pipe connectors

9) 1 quick-connector

10) 1 bag connector

11) 5 m2 release fabric

12) 5 m2 perforated film

13) 5 m2 breather fabric

14) 5 m2 vacuum bagging film (2.08 X 2.40 m)

15) 21 m mastic sealant

Intrastat Number for this product: 85184000..

236.00€

420.00 EUR / kit

This set of products is everything needed to perform vacuum bagging operations. It includes:

1) 1 vacuum pump (large size)

2) 1 air filter

3) 6 m rigid pvc pipe

4) 1 distributor

5) 1 negative manometer

6) 1 control valve

7) 3 air-taps

8) 3 pipe connectors

9) 1 quick-connector

10) 1 bag connector

11) 5 m2 release fabric

12) 5 m2 perforated film

13) 5 m2 breather fabric

14) 5 m2 vacuum bagging film (2.08 X 2.40 m)

15) 21 m mastic sealant

Intrastat Number for this product: 85184000..

420.00€

298.00 EUR / kit

This set of products is everything needed to perform plain vacuum bagging as well as vacuum infusion operations. It includes:

1) 1 vacuum pump (medium size)

2) 1 air filter

3) 6+8 meters rigid pvc pipe

4) 1 distributor

5) 1 negative manometer

6) 1 control valve

7) 3 air-taps

8) 3 pipe connectors

9) 1 quick-connector

10) 1 bag connector

11) 10 m2 release fabric

12) 10 m2 perforated film

13) 10 m2 breather fabric

14) 10 m2 vacuum bagging film (4.17 X 2.40 m)

15) 10 m2 flow fabric

16) 2 X 21 m mastic sealant

17) 25 m spiral tube

18) 8 T joints

19) 1 tube clamp

20) 1 spray adhesive

21) 1 X 1.5 lt stainless steel + aluminum, exotherm safe resin trap pot

22) 1 step by step DVD movie showing the infusion process

Intrastat Number for this product: 84141025..

298.00€

482.00 EUR / kit

This set of products is everything needed to perform plain vacuum bagging as well as vacuum infusion operations. It includes:

1) 1 vacuum pump (large size)

2) 1 air filter

3) 6+8 meters rigid pvc pipe

4) 1 distributor

5) 1 negative manometer

6) 1 control valve

7) 3 air-taps

8) 3 pipe connectors

9) 1 quick-connector

10) 1 bag connector

11) 10 m2 release fabric

12) 10 m2. perforated film

13) 10 m2 breather fabric

14) 10 m2 vacuum bagging film (4.17 X 2.40 m)

15) 10 m2 flow fabric

16) 2 X 21 m mastic sealant

17) 25 m spiral tube

18) 8 T joints

19) 1 tube clamp

20) 1 spray adhesive

21) 1 X 1.5 lt stainless steel + aluminum, exotherm safe resin trap pot

22) 1 step by step DVD movie showing the infusion process

Intrastat Number for this product: 84141025..

482.00€

This set of products are needed to perform repairs. It includes:

1) 1 kg 482 epoxy resin + 0.50 kg med. speed hardener (see here)

2) 2 m2 carbon fabric C160P (width 0.17 m)

3) 1 lt microfibers

4) 1 lt glass bubbles

5) Internet resources with detailed instructions on repairing

All fabrics in this kit are folded up (not rolled), in order to facilitate shipping

Intrastat Number for this product: 84141025..

61.00€

99.00 EUR / kit

This set of products are needed to perform repairs. It includes:

1) 1 kg 482 epoxy resin + 0.50 kg med. speed hardener (see here)

2) 5 m2 carbon fabric C160P (width 0.17 m)

3) 1 lt microfibers

4) 1 lt glass bubbles

5) Internet resources with detailed instructions on repairing

All fabrics in this kit are folded up (not rolled), in order to facilitate shipping

Intrastat Number for this product: 84141025..

99.00€

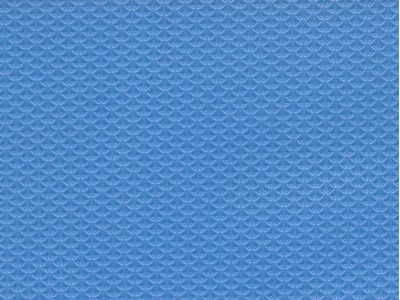

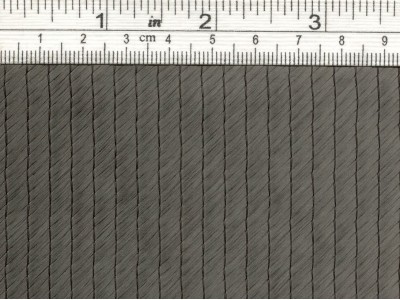

Width: 1.30 meters

Thickness: 70 μ

Embossing film, with heavier imprinted texture, used to facilitate the impregnation of prepregs, usually with SR8500 / KTA311 (but also other, colder curing) epoxy systems. It is texturized in such a way so to facilitate air to escape, or drive air out of the impregnating laminate. It is also used as a protective liner that separates prepreg layers.

Intrastat Number for this product: 39206212..

1.56€

Width: 1.30 meters

Thickness: 50 μ

Embossing film, with lighter imprinted texture, used to facilitate the impregnation of prepregs, usually with SR8500 / KTA311 (but also other, colder curing) epoxy systems. It is texturized in such a way so to facilitate air to escape, or drive air out of the impregnating laminate. It is also used as a protective liner that separates prepreg layers.

Intrastat Number for this product: 39206212..

1.12€

Price: 148.50 EUR / reel of 1.80 kg

Carbon fiber type: TR30S 3L A1

Total weight: 1.8 kg

Total length: 5,000.00 m

MECHANICAL PROPERTIES OF CARBON FIBER

Tensile strength (MPa): 4433

Tensile modulus (GPa): 231

Elongation at break (%): 1.8

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibremax Ltd reserves the right to change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses.

Intrastat Number for this product: 68151200..

148.50€

Price: 195.00 EUR / reel of 4 kg

Carbon fiber type: TR50S

Total weight: 4 kg

Total length: 4,000.00 m

MECHANICAL PROPERTIES OF CARBON FIBER

Tensile strength (MPa): 4661

Tensile modulus (GPa): 240

Elongation at break (%): 1.9

DISCLAIMER

All information herein is given for guidance and general information purposes only, represents typical properties, and should not be used for specification limits purposes or basis for design. Fibremax Ltd reserves the right to change yarns, specifications, and all information given herein, without notice. It is only on written certificates and agreements that we provide our customers with warrants for the quality and/or advise for the suitability of products for particular uses.

Intrastat Number for this product: 68151200..

195.00€

30.00 EUR / 2 kg container

Precisely chopped mix of 3K and 6K carbon fibers with 12 mm length suitable for reinforcing composite materials. They're often blended with matrix materials like epoxy or polyester resin to enhance the mechanical properties of composites or for cosmetic purposes. They are also used to improve electrical and thermal conductivity.

TYPICAL MECHANICAL PROPERTIES OF CARBON FIBER USED

Tensile strength (MPa): 4120 (3Κ), 4900 (6Κ)

Tensile modulus (GPa): 235

Elongation at break (%): 1.8 (3Κ) 1.9 (6Κ)

Intrastat Number for this product: 68151200..

30.00€